How to Plug-And-Play?

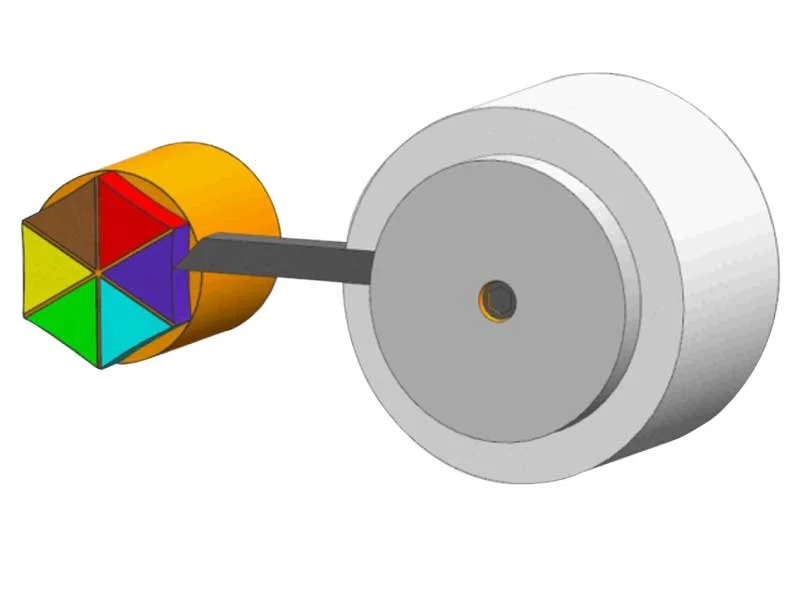

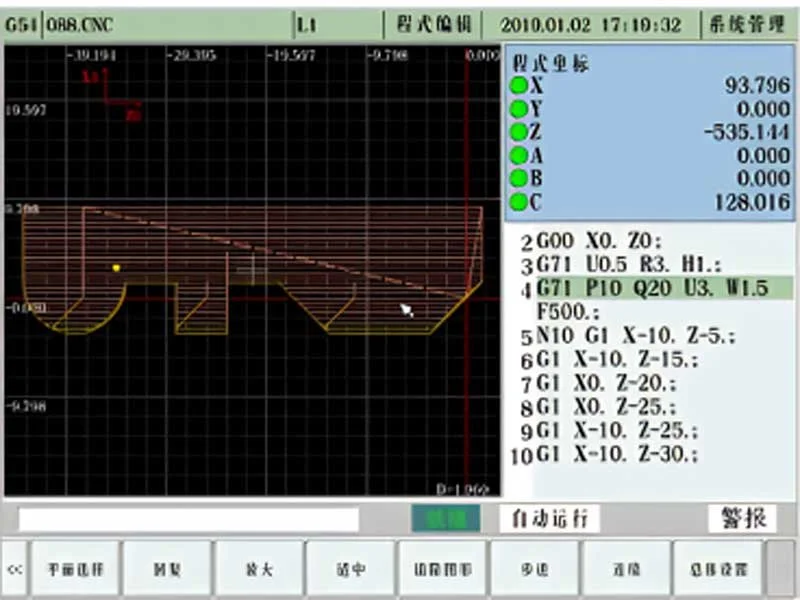

Our SmartBrain CNC programming language acts as the brain in our CNC turning machines. For the ability to machine simple parts to those that are complex and require multi-tasks like turning-milling operations, SmartBrain offers you the versatility and flexibility to program those parts using either G-code/M-code programming (EIA/ISO) or Manual Data Input(MDI).

|

Control method |

Bus control method |

|

Use type |

Turn-milling lathe with Y-AXIS |

|

Number of input and output |

32IN/32OUT |

|

Number of linkage axes |

4(XYZC) |

|

Applicable models |

SL-series |

Special Features

|

System Specifications |

|

|

Installation Method |

Horizontal |

|

Standard Number of Axes |

8 |

|

Maximum Linkage Axes per Channel |

4(XYZC) |

|

Standard Number of Spindles |

1 |

|

Display Screen Size |

8.4"/10.4"/15" |

|

Axis Distribution |

XYZABC + Tool Turret + Servo Tailstock |

|

Memory |

1GB |

|

Program Capacity |

8GB |

|

Pre-read Blocks |

4000 Block/S |

|

Maximum Tool Compensation Groups |

160Groups |

|

Transmission |

USB/RS232/RS485/LAN/WIFI |

|

Fieldbus Support |

EtherCAT |

|

Fieldbus Spindle |

Supported |

|

Standard I/O |

I32/O32 |

|

Communication Function |

ModbusTcp/RS232/RS485 |

|

Programming Commands |

|

|

(G-Code) |

Complies with international standards |

|

Macro Programming Standards |

Supported (Macro B/Macro C) |

|

Dialog Programming |

Supported |

|

Program U-Disk Transfer |

Supported |

|

Automatic Program Error Detection |

Supported |

|

Program Lock Function |

Supported |

|

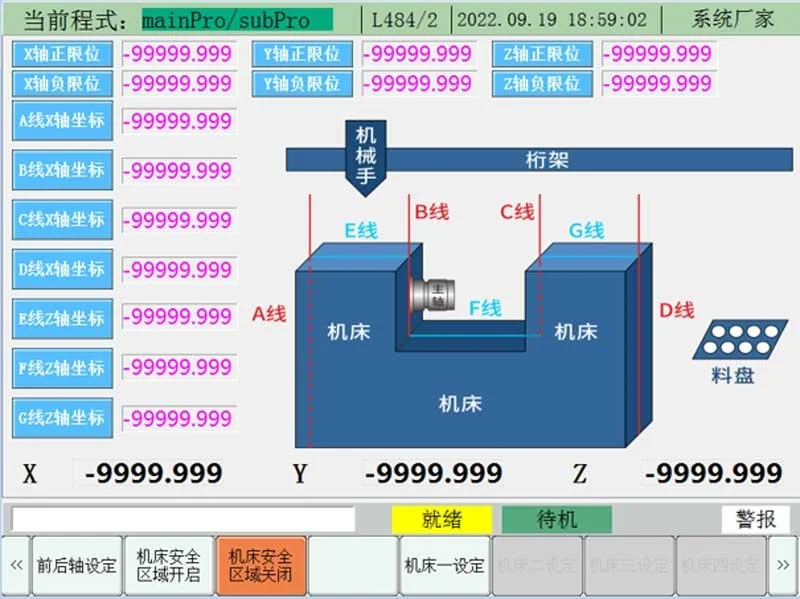

Robot |

|

|

Independent channel control for robots |

Supported |

|

Turret |

|

|

Turret type |

Power turret/Hydraulic turret/Servo turret |

|

High-Speed and Precision |

|

|

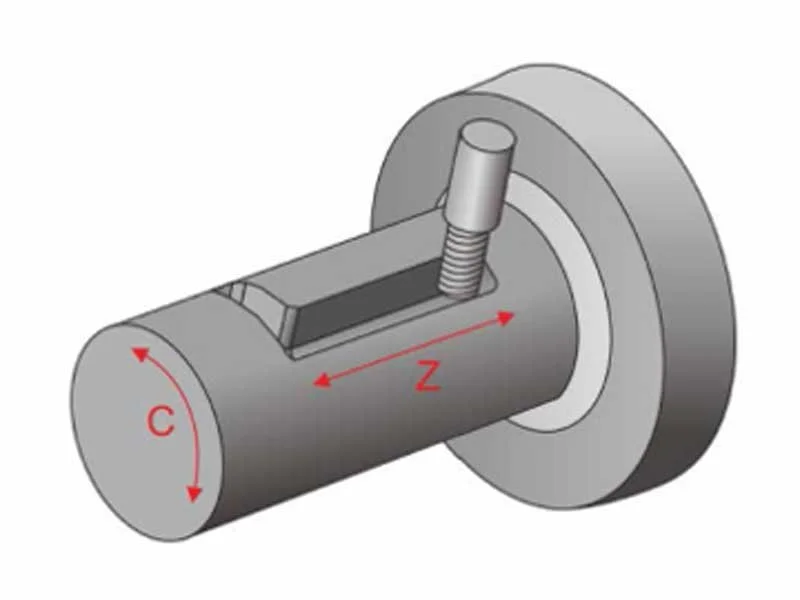

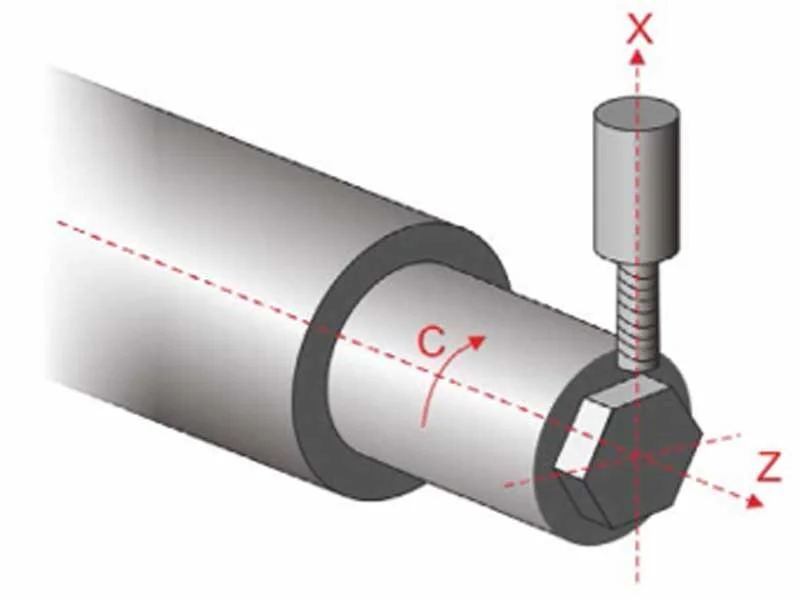

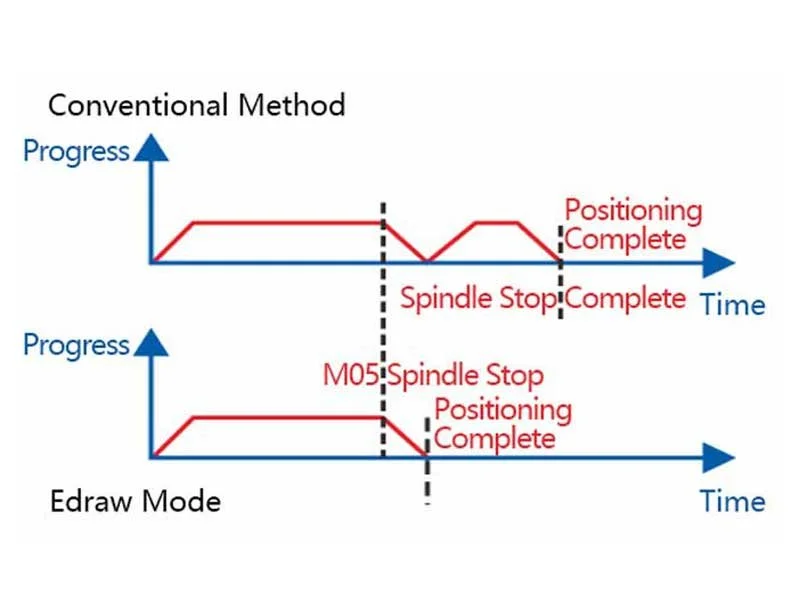

Spindle C-Axis Dynamic Positioning |

Supported |

|

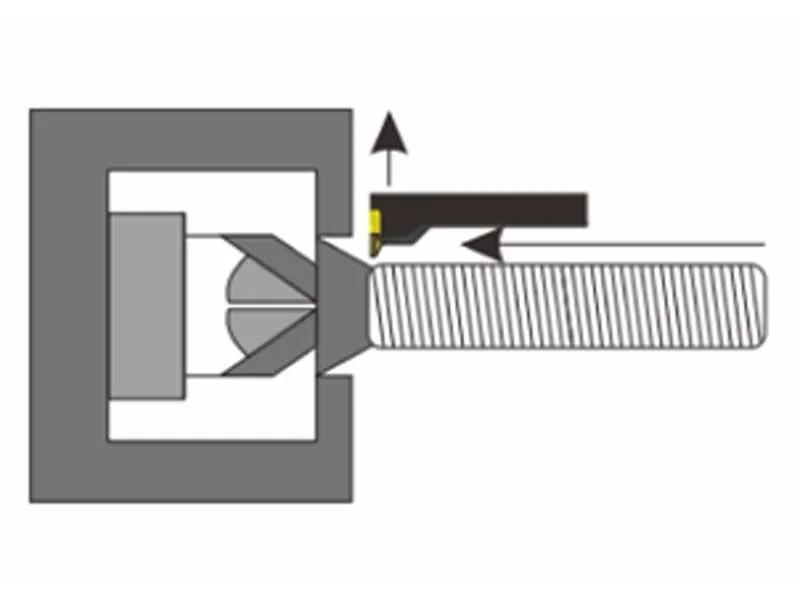

Rapid Tool Retraction for Turning/Drilling |

Supported |

|

Non-stop Block Skipping Mode |

Supported |

|

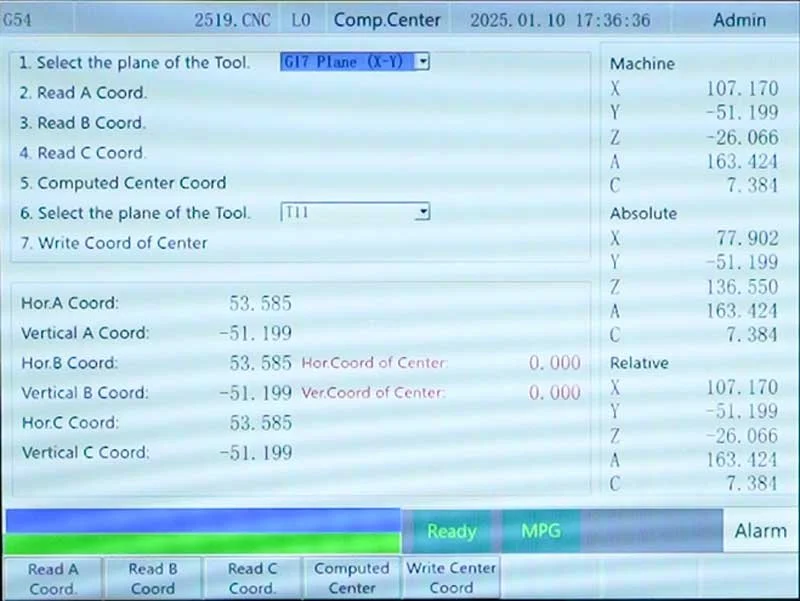

Compensation Functions |

|

|

Linear Compensation |

Supported |

|

Backlash Compensation |

Supported |

|

Arc Sharp Angle Compensation |

Supported |

|

Dual-Screw Error Compensation |

Supported |

|

Forward Compensation |

Supported |

|

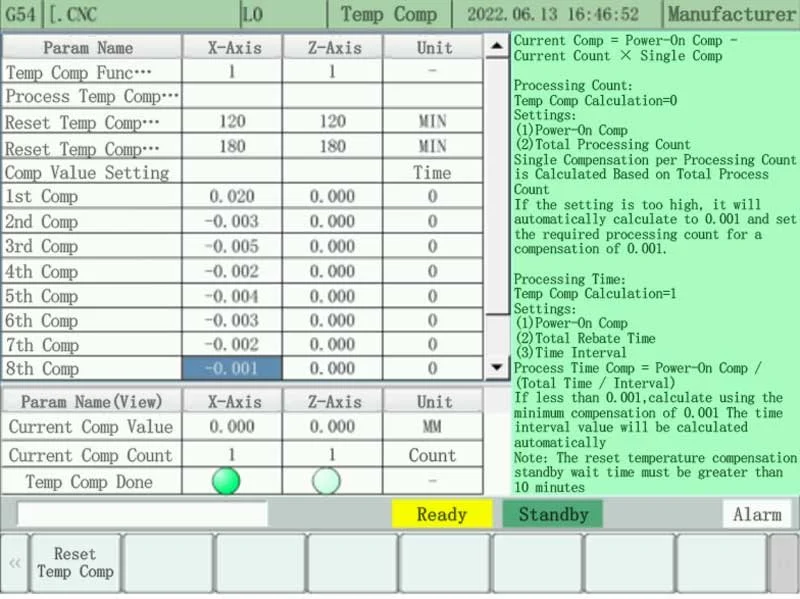

Cold/Hot Machine Temperature Compensation |

Supported |

|

Cutting Functions |

|

|

Bezier Curve Interpolation |

Supported |

|

Elliptical Interpolation |

Supported |

|

Cylindrical Interpolation |

Supported |

|

3D Helical Interpolation |

Supported |

|

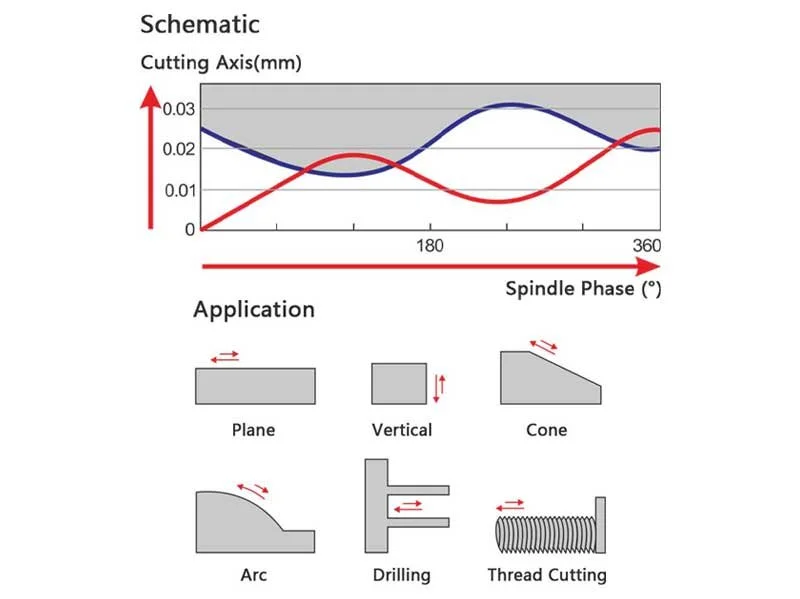

Polygon Turning (with Fly Cutter) |

Supported |

|

Polar Coordinate Interpolation |

Supported |

|

Drilling |

Supported |

|

Thread Cutting |

Supported |

|

Grooving |

Supported |

|

Auxiliary Functions |

|

|

Custom M-Code |

Supported |

|

Custom G-Code |

Supported |

|

I/O Redefinition Function |

Supported |

|

Tool Life Management |

Time-based and usage-based management |

|

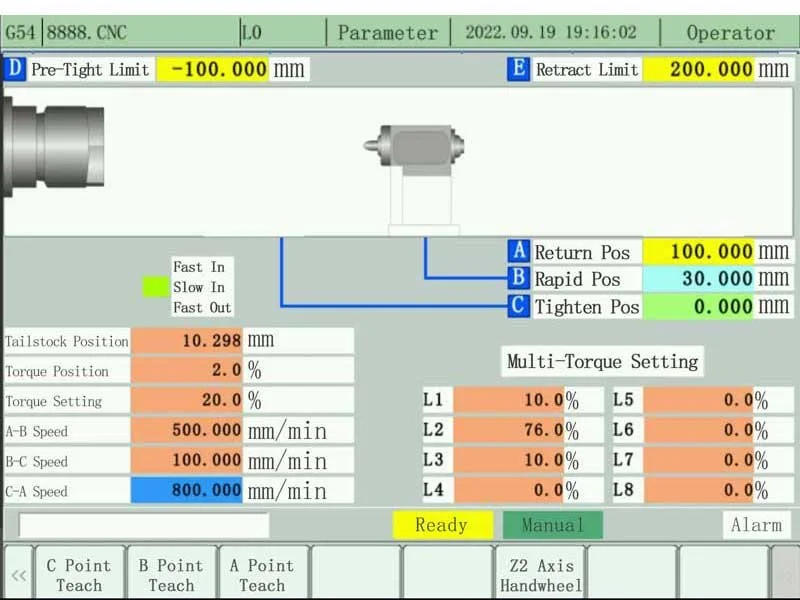

Protection Function |

Safety doors, hard limits, soft limits, tailstock unclamped detection, tool turret tool change monitoring |

|

Handwheel Simulation |

Supports handwheel preview and return functions |

|

Restart Function |

Program breakpoint automatic search restart/custom restart |

|

Graphic Simulation |

Program preview before execution/program dynamic simulation during execution |

|

Axis Load Monitoring |

Supported |

|

Spindle Speed Achieved Detection |

Supported |

|

Data Backup |

Program backup, parameter backup, tool compensation backup |

|

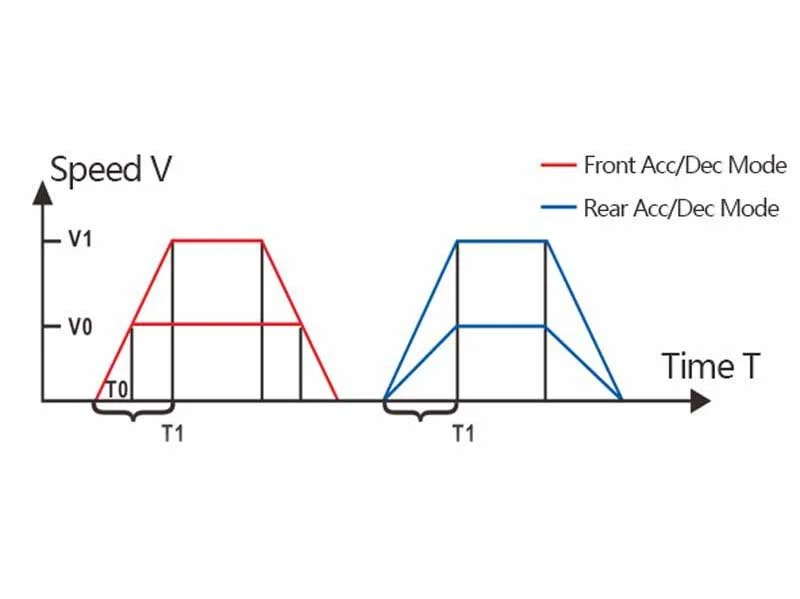

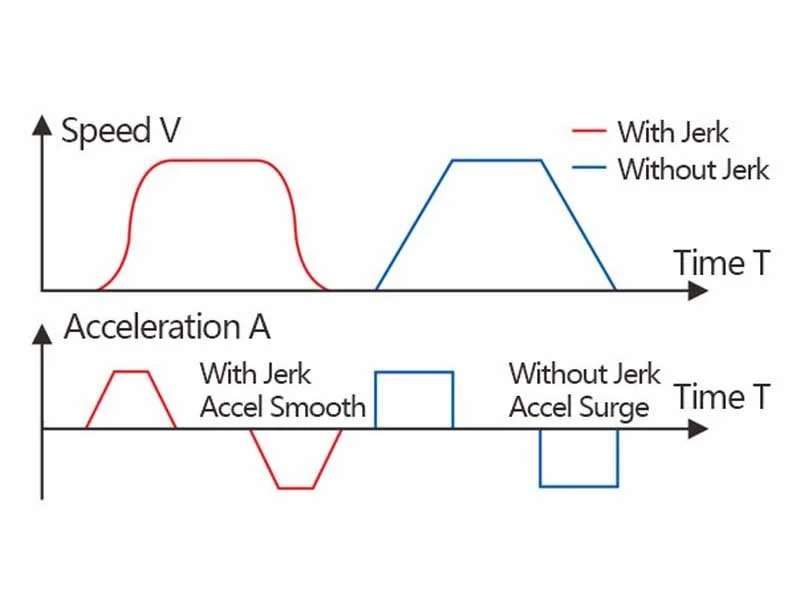

Acceleration and Deceleration Types |

Linear (constant) / S-curve (constant JERK) |

|

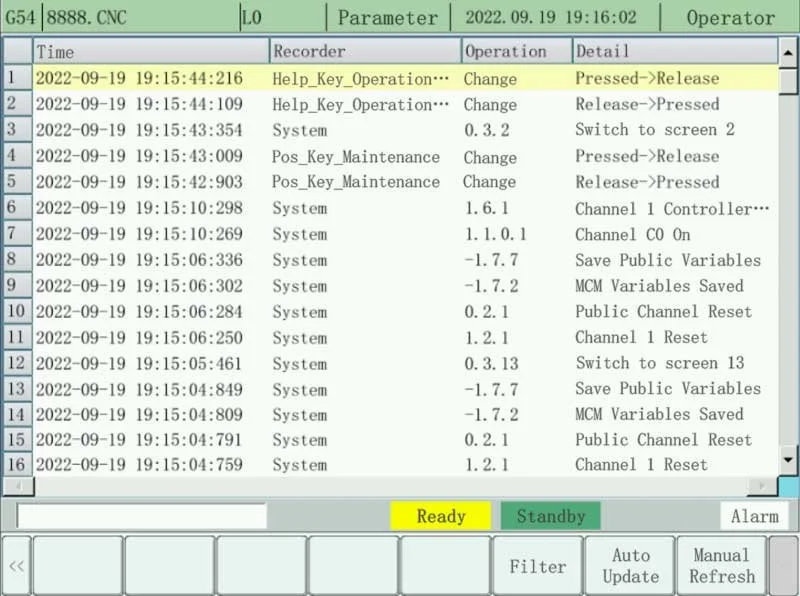

Permission Management |

Privilege and operation rights management |

|

Oscilloscope Function |

Real-time monitoring of system commands and servo feedback waveforms |