Modularized Design

Ensure Highly Consistency and Engineering Precision.

Competitive Price & Ready-to-Ship Models are Available.

Standardized Production

Customized Solution

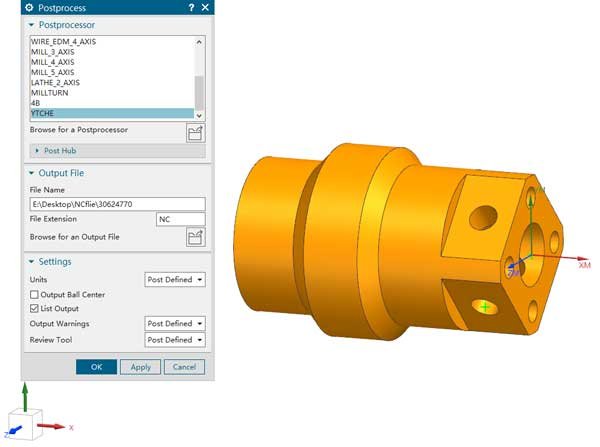

Technical Support with Machining Analysis & Optimism.

Why Smartlathe

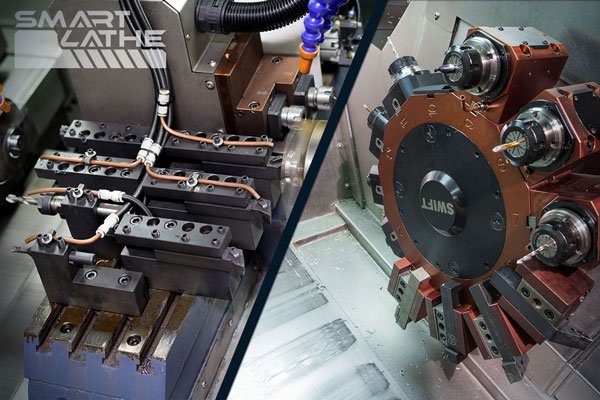

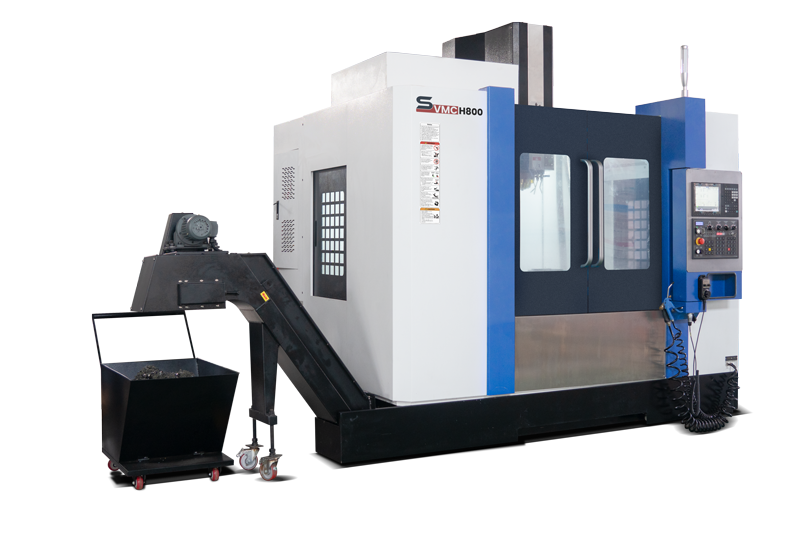

SmartLathe concentrated all its resources to develop successfully the typical series of CNC slant bed lathes including the SL series-gang type CNC lathe to help our customers in the field of prototyping, entry-level business, and the craftsman with a bootstrap budget, ST series-Power Turret CNC lathe for the complex mill-turn processing and DS series-Dual Spindle CNC Turning-Milling machines for the pursuit of high accuracy and high productivity. In addition, we have introduced the impact and powerful VMC Series vertical machining centers to meet the diverse milling needs of our customers.

Customer Cases

OUR PRODUCTS

Slant Bed

Gang Type

Gang type

Servo Spindle

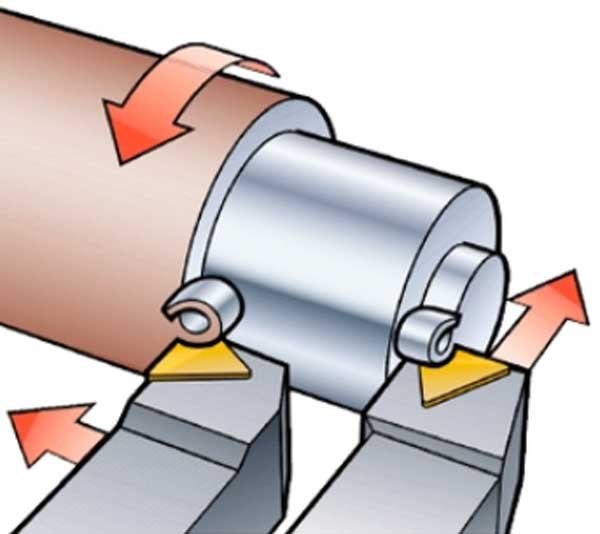

Living Tools

Collet

Y-Axis Milling

Y-Axis Turret Type

Power Turret

Tailstock

High Rigidity

Dual Spindle

Dual Spindle

Gang Type

Automatic

Turret Type

Turning & Milling

Swiss Type

Swiss Type

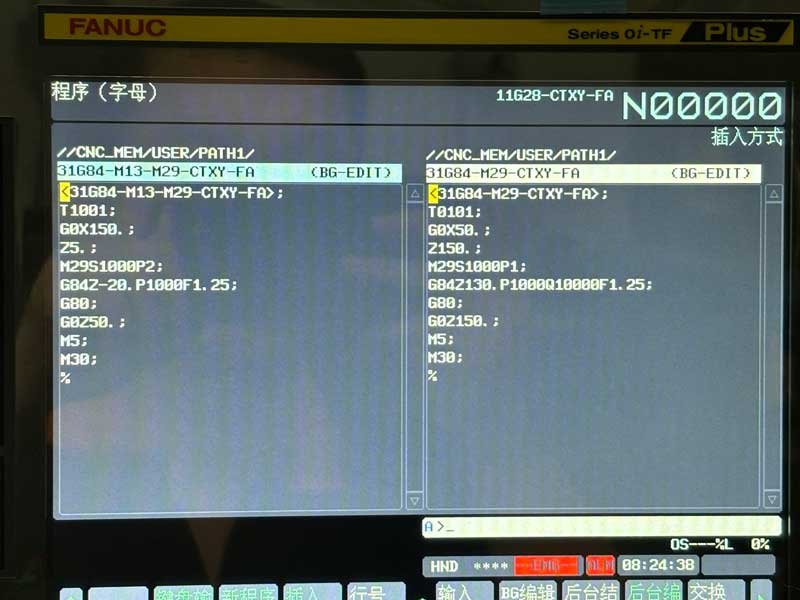

Dual Channel System

Carousel

Toolroom

BT30/40

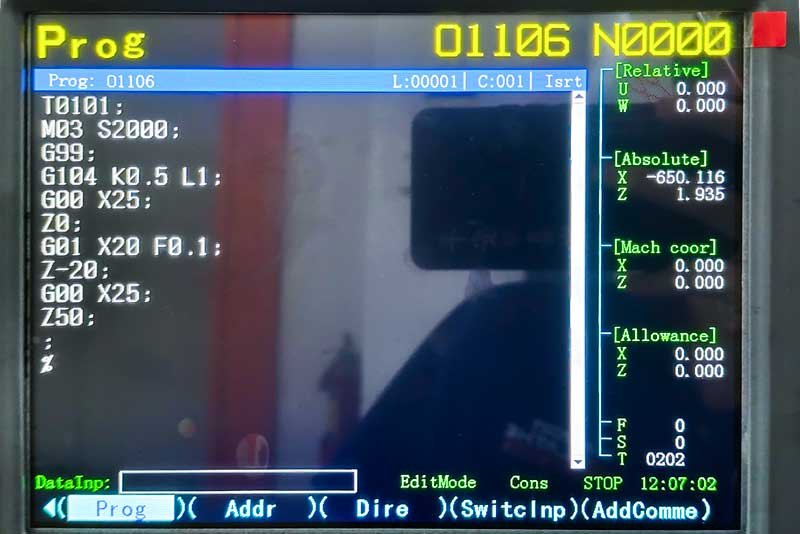

Smartbrain System

Synchronous-action

Drill & Tap

BT30/40 High-speed

high rigidity

Side-mounted

High Performance

BT40

Heavy Duty

AUTOMATIC SOLUTIONS

At Smartlathe CNC, we pride ourselves on being a leading supplier of reliable, stable, and cost-effective CNC lathes. Beyond providing high-quality machines, we also offer comprehensive automation solutions to enhance your production efficiency. Our primary automation options include truss manipulators and robotic arms. These automated CNC lathe solutions significantly boost productivity while reducing manual labor intensity.

Our robotic arm solution provides a versatile and flexible automation option for CNC lathes. Capable of performing a wide range of tasks, from material handling to complex machining operations, these robotic arms can be programmed to meet specific production requirements. They offer high levels of precision, repeatability, and adaptability, making them suitable for various manufacturing processes. Additionally, the use of robotic arms can significantly reduce labor costs and improve workplace safety by taking over repetitive and hazardous tasks.

The truss manipulator offered by Smartlathe CNC is designed for seamless integration with our CNC lathes. This system automates the process of loading raw materials and unloading finished products, ensuring a continuous workflow and minimizing downtime. Key features include high precision, fast operation speeds, and robust construction, making it ideal for high-volume production environments. By implementing this system, manufacturers can achieve greater consistency in production and reduce the risk of human error.

Configurations on Demand

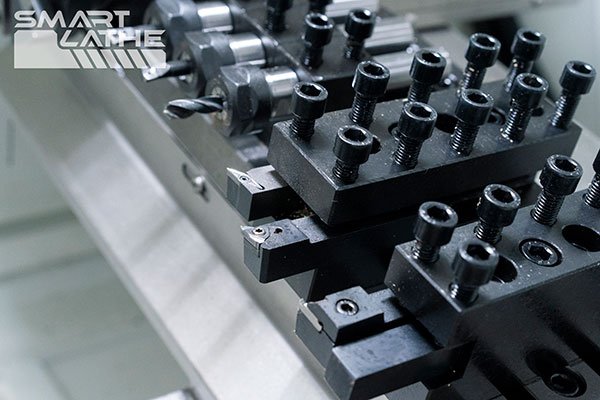

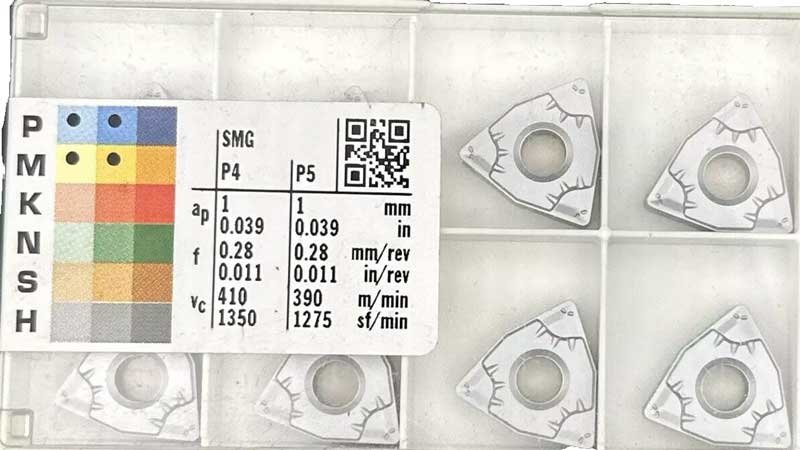

Thanks to the modularized designs, Smartlathe is capable of providing the various multi-functional tools & fittings to perfectly match the tailored machining requirements.

Y-axis Living Tools

3 Jaws Chuck

Servo Turret

Step Type Live Tools

Oil Bar Feeder

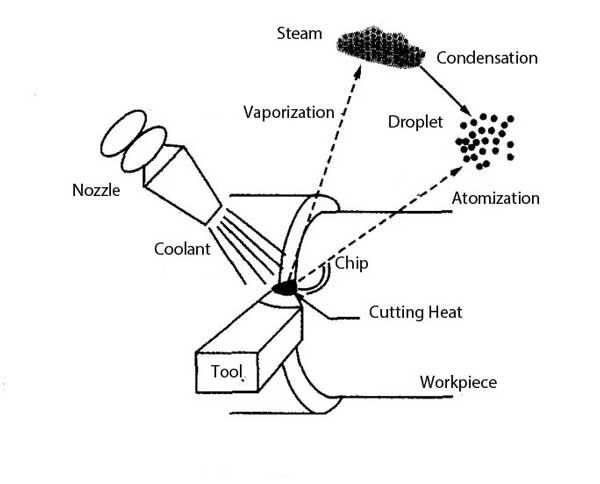

Oil Mist Collector

Servo Bar Feeder

4+4 Living Tools

Tools Setter

Power Turret

Part Catcher

Tailstock

We Extend the Limit of CNC Turning Process!

Chip Conveyor

4th Axis

Auto Tools Setter

Customized Fixture

Send us a drawing to evaluate.

STEP / STP / SLDPRT / PRT / DWG / DXF files.

All files are secure and confidential.