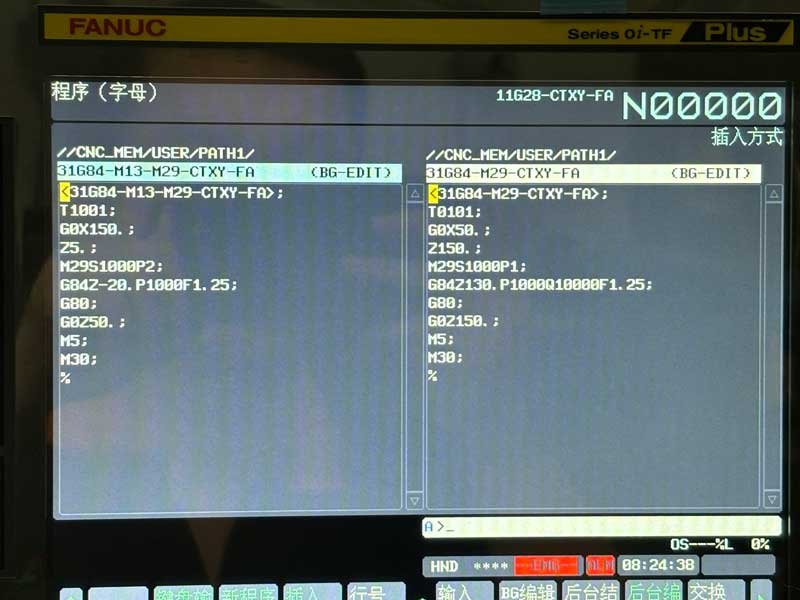

Differences in programming between Fanuc and GSK

Both systems support ISO standard G-codes such as G01, G02, G03, etc. The basic programming logic is similar.

CNC Tool Classification

In modern manufacturing, CNC lathes have become indispensable processing equipment. As the "teeth" of CNC lathes, tools play a crucial role in determining machining efficiency and product quality. This article will help you understand the classification and characteristics of CNC lathe tools, enabling you to select the most suitable tools for your production needs.

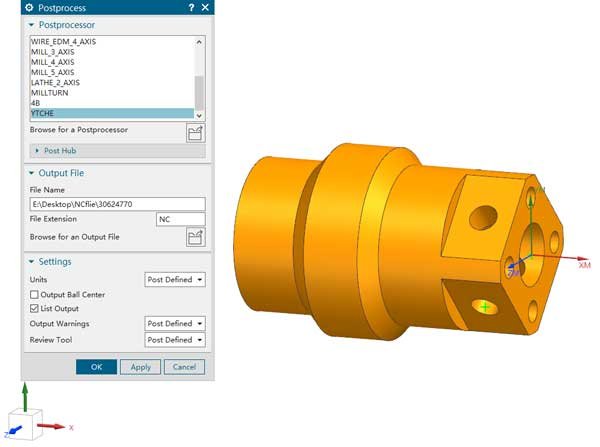

NX post-processing import and machine head connection settings

NX post-processing import and machine head connection settings

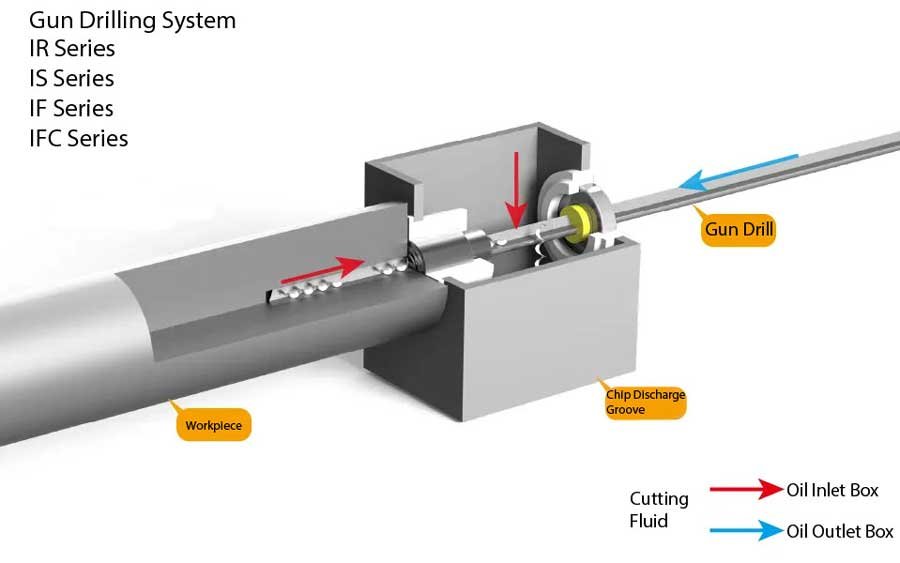

What is Deep Hole Drilling?

A deep hole is defined by its depth-to-diameter ratio (D:d), and typically holes greater than 10:1 are considered deep holes. Deep hole machining is widely used in manufacturing industries such as aerospace, automotive, mold, and energy.

The influence of drill bit geometry on drilling

As the most commonly used cutting tool in the machining process, the drill bit's geometry directly affects the drilling efficiency, hole diameter accuracy, surface roughness, and the durability and life of the drill bit. In the drill bit geometry design, the top angle, helix angle, core thickness, chisel edge shape, edge modification, and surface coating are key parameters.

Nickel Alloy Machining Methods

Nickel alloy is a kind of metal material with nickel (Ni) as the main component and other metal elements (such as chromium, iron, molybdenum, copper, aluminum, titanium, etc.) added to improve specific properties. Due to its excellent corrosion resistance, high temperature strength and oxidation resistance, nickel alloy is widely used in aerospace, nuclear energy, marine engineering, petrochemical, medical equipment and other fields.

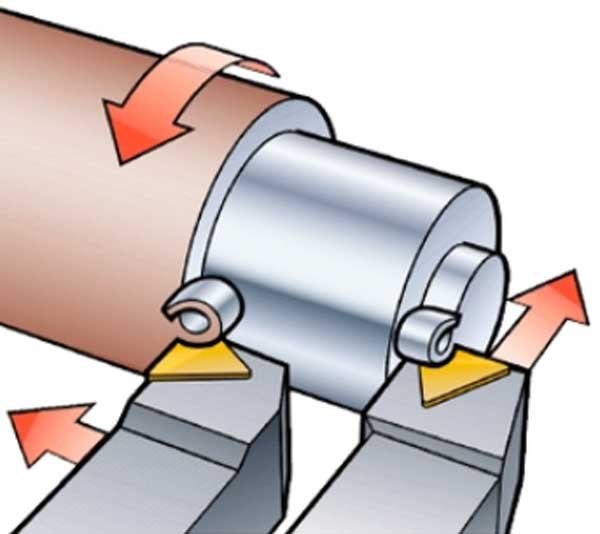

How to use a double-spindle lathe for polygonal butt jointing?

In modern precision machining, dual-spindle machines have become the industry focus due to their unique design and efficient machining capabilities. Multi-polygon alignment, as an emerging machining technique, demonstrates exceptional processing efficiency and product quality with the support of dual-spindle machines. This article will explore the technical features of dual-spindle multi-polygon alignment solutions and their advantages in practical applications.

What is countersinking

Countersinking is a metal processing method that refers to processing cylindrical countersunk holes, conical countersunk holes, and boss end faces on processed holes.

Cradle type five-axis Vertical Machining Center

The cradle-type 5-axis machining center is an important branch of the five-axis linkage machine tool. Its core feature is that the worktable adopts a "cradle" structure to realize the two-axis rotation and tilt of the workpiece, thereby forming a five-axis linkage processing method with the spindle. The five-axis machining center is a high-precision and high-efficiency CNC machine tool equipment that can control five axes for processing at the same time, usually including three linear axes (X, Y, Z axes) and two rotation axes (A, B or C axes).

What is a push-type chuck?

A push-type chuck is a workpiece holding device commonly used in turning operations. Known for its efficient and precise clamping, it is widely employed in various CNC machine tools, especially in scenarios requiring high repeat positioning accuracy and stable clamping force.

Common Types of CNC Horizontal Deep Hole Drilling

CNC horizontal deep hole drilling is a machining technology used for processing holes with large depths. It is widely applied in industries such as energy machinery, aerospace, hydraulic equipment, and petrochemicals. The machine features a horizontal spindle arrangement, with the workpiece fixed to the bed, while the drilling tool operates with high rigidity and precision. Horizontal deep hole drilling offers good machining stability and efficient chip removal, making it especially suitable for deep hole processing in long workpieces. Common types of CNC horizontal deep hole drilling include: gun drilling, BTA drilling, deep hole rolling, and electrical discharge machining (EDM).

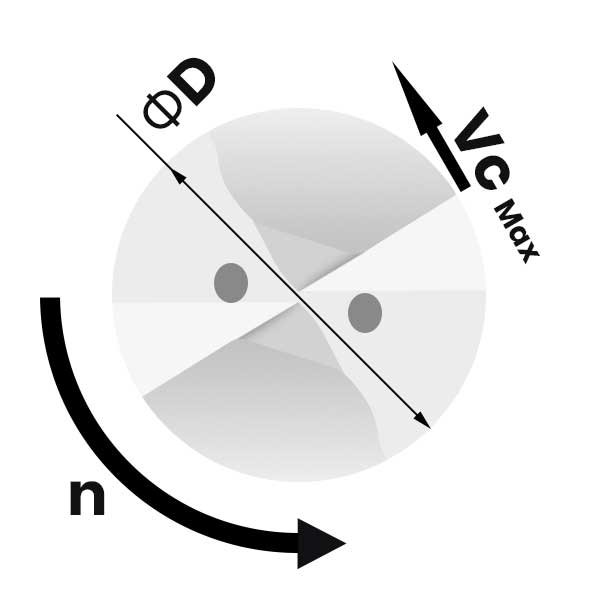

Calculation of drilling parameters

Cutting speed is the relative linear speed between the cutting edge and the workpiece. At every point, the cutting speed is the product of the drill's rotational speed (spindle speed) and the circumference. At the center of the drill, the cutting speed is always zero, and it gradually increases as you move away from the center. Therefore, in drilling, the term "cutting speed" refers to the maximum cutting speed occurring at the drill's outer diameter. On the surface of the drill, the cutting speed varies according to the distance from the center.

How do you do blind hole tapping?

Unlike through holes, blind holes do not pass through the workpiece. They have a bottom, which is why blind holes are often referred to as guide holes. The bottom of the hole is also a potential issue for blind hole threads, which does not occur with through holes. If not handled properly, chips can accumulate in the blind hole. Additionally, the tap may collide with the bottom of the blind hole and break, or other problems may arise. Those who frequently use taps with blind holes often encounter these issues. The primary solution to this problem is to avoid misalignment and prevent the blind hole thread from becoming larger than intended.

Servo Turret and Hydraulic Turret on CNC Lathes

Servo turrets and hydraulic turrets are two commonly used turret types in CNC lathes. They differ significantly in structure, operating principles, and application scenarios, particularly in terms of drive method, control precision, structural design, and operational performance.

How to Choose Hard Jaws and Soft Jaws, and How to Properly Adjust

Soft jaws are versatile and can be machined to fit specific workpieces, ensuring precise gripping and reducing the risk of damage, making them ideal for delicate or unique tasks. Hard jaws, on the other hand, are pre-hardened, durable, and suitable for repetitive or high-torque operations, providing strong and consistent clamping. Soft jaws excel in flexibility and customization, while hard jaws prioritize longevity and efficiency for standard applications. Both are essential depending on the machining requirements.

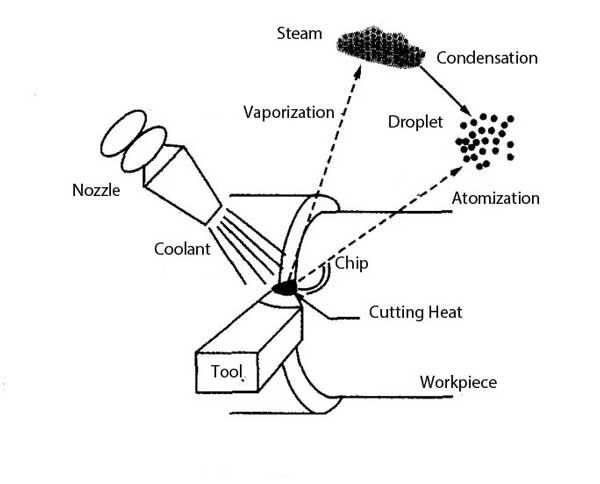

Oil Mist Generated in CNC Lathe Processing

During metal processing with CNC lathes, a large amount of cutting fluid is used, leading to the formation of numerous oil mist particles in the air. Metalworking lubricants are complex mixtures that, in addition to hydrocarbons, often contain sulfonates, fatty amines, nitrates, dyes, biocides, and other chemicals. If the lubricant has been in use for some time, due to the oxidation of hydrocarbons, microbial growth, or contamination by external impurities, it may contain additional chemicals that are harmful to both humans and the environment. Therefore, controlling the concentration of oil mist in metalworking workshops is a crucial measure for ensuring occupational safety and health in production enterprises.

Surface Treatment for Workpieces After Vertical Machining Center (VMC) Processing

CNC machining processes are capable of producing precise parts and components with strict tolerances of ±0.025 mm and intricate details. However, parts manufactured by a vertical machining center (VMC) often exhibit noticeable machining marks. Therefore, surface treatment is a critical aspect of the manufacturing process, enhancing the aesthetic appeal, corrosion resistance, wear resistance, and other physical and functional properties of metal parts post-VMC processing. Different types of surface treatments involve varying procedures and results, making it essential to understand the basics to select the most suitable option.

What are the main CNC machining parameters? (Turning)

CNC machining relies on precise parameter settings to ensure accuracy and repeatability. The proper setting of machining parameters determines the quality and efficiency of the machining process. These settings include spindle speed, feed rate, depth of cut and cutting tool path.

Classification of Cutting Fluids

Cutting fluids are widely used in CNC lathe machining environments, continuously injecting vitality and efficiency into metal cutting operations through flexible application methods such as precise injection, fluid spraying, or fine mist.

Types and Characteristics of Vertical Machining Center (VMC) Tool Holders

A VMC tool holder is a critical device used in VMC for securing and clamping tools. Its primary function is to firmly fix the tool to the spindle during machining, ensuring the concentricity and rigidity between the tool and the spindle. This is essential for maintaining machining accuracy and stability.