Advantages and Applications of VMC (Vertical Machining Centers)

1. Advantages of VMC Machines

High Precision and Accuracy

VMC machines provide higher precision and accuracy in machining operations. With advanced CNC technology and precise control systems, these machines can meet strict tolerance requirements and continuously produce high-quality parts. The accurate positioning capability of cutting tools enables VMC machines to perform complex machining tasks with minimized errors or deviations, making them suitable for tasks requiring high detail.

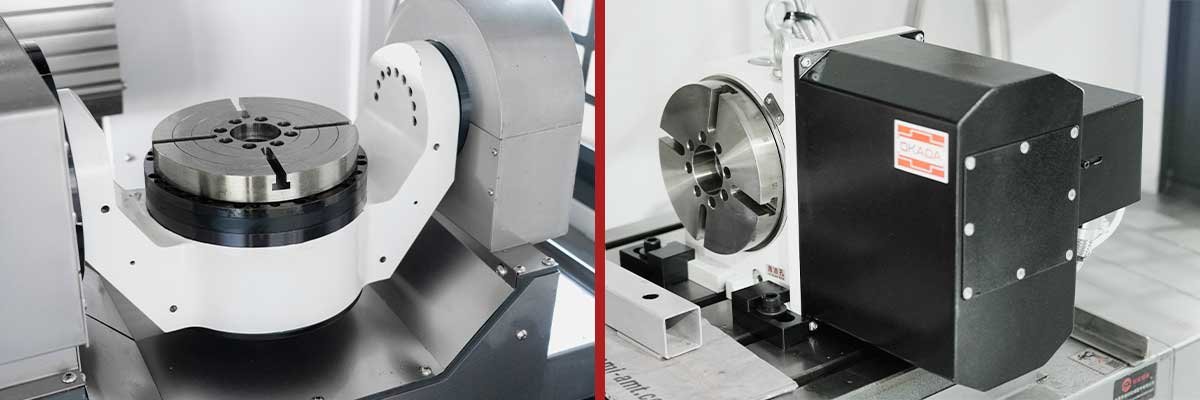

Multi-Axis Machining for Increased Efficiency

VMC machines are equipped with multiple axes, allowing simultaneous operations that reduce the need for multiple setups and significantly shorten machining cycles. Additionally, powerful spindle motors accelerate material removal. Coupled with fast tool-changing systems that minimize downtime between operations, overall production efficiency is further enhanced.

Greater Flexibility and Versatility

VMC machines offer great flexibility and versatility in machining applications. They can handle various materials, including metals, plastics, and composites. With their multi-axis capability, VMC machines can perform complex milling operations such as contour milling, drilling, tapping, threading, and slotting.

These characteristics make VMC machines ideal for a wide range of industries and applications. They excel in high-precision and complex tasks, and can efficiently and stably process materials and parts of different sizes.

2. Applications of VMC Machines

Due to their powerful functions, high precision, and high production efficiency, VMC machines are widely used in various fields:

Aerospace Industry

VMC machines play a critical role in the aerospace industry, where precision and reliability are key requirements. These machines are used to manufacture complex components such as turbine blades, engine parts, and aircraft structures. With their advanced capabilities, VMC machines ensure the high precision and strict tolerances needed in aerospace applications.

Automotive Industry

VMC machines are widely used in the automotive industry to produce components like engine blocks, transmission parts, and braking systems. Since they can perform multiple operations in a single setup, these machines simplify the manufacturing process and improve productivity.

Medical Industry

The medical industry relies on VMC machines to manufacture complex medical devices such as implants, surgical instruments, and prosthetics. VMC machines can precisely machine complex shapes with tight tolerances, meeting the stringent demands of the medical field.

Electronics Industry

In the electronics industry, VMC machines are used to produce circuit boards, connectors, and other electronic components that require high precision. These machines ensure precise drilling and complex milling patterns on fine materials such as PCBs (printed circuit boards).

Molding and Stamping Industry

The molding and stamping industry heavily depends on VMC machines to produce molds used in manufacturing processes like injection molding or die-casting. These machines provide the necessary precision to produce complex mold cavities with tight tolerances.