SYNTEC CNC LATHE CONTROLLER

SYNTEC is a Taiwan well-recognized CNC control system. Cause its easy-to-use and stability, it is highly favored in the CNC industry. Smartlathe is highly compatible with SYNTEC and is available in Chinese, English and Russian.

|

Control method |

Bus control |

|

Use type |

Turn-milling lathe with Y-AXIS |

|

Number of input and output |

32 IN/32 OUT |

|

Number of linkage axes |

4(XYZC) |

|

Applicable models |

SL-X/SL-52YT/ST-series/DS-series |

Special Features

-

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Lathe-Friction-Compensation-Function-VFF]()

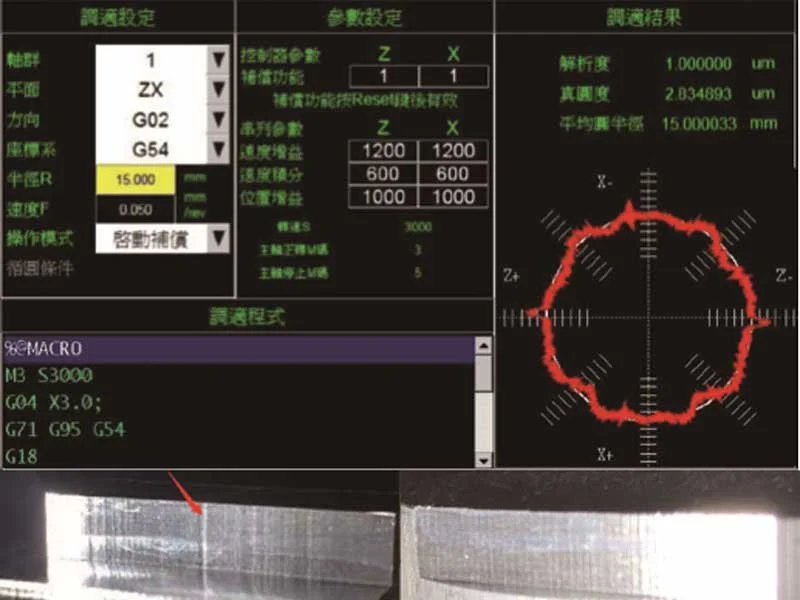

Lathe Friction Compensation Function (VFF)

Reduce friction (sharp corners) during commutation

Automatic parameter adjustment, simple and fast

Supports multiple sets of RF adjustment (five sets), which can compensate for different radii and speeds.

-

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Inclined-surface-machining]()

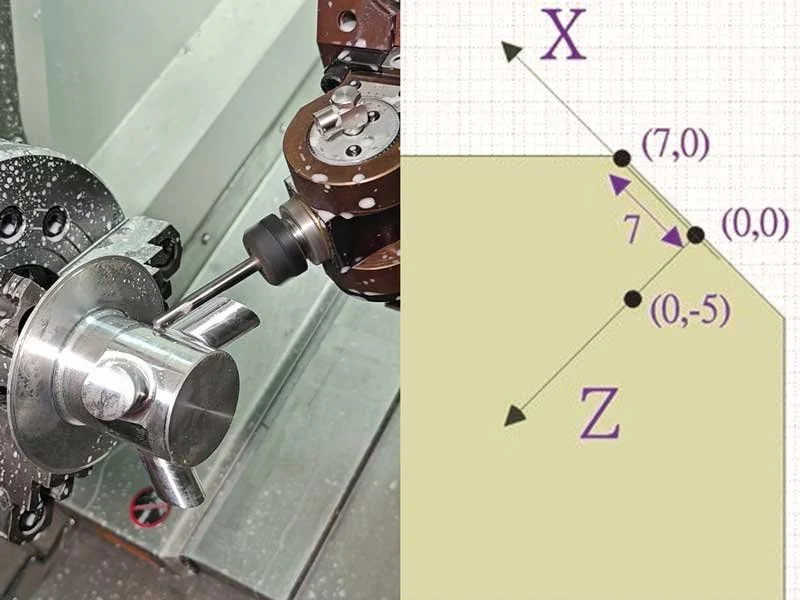

Inclined Surface Machining

By rotating the program coordinate system, you can easily write the machining program on the inclined surface. Milling, drilling, and tapping on the inclined plane can all be realized by simply writing NC programs. No complicated CAD/CAM processing is required.

-

![]()

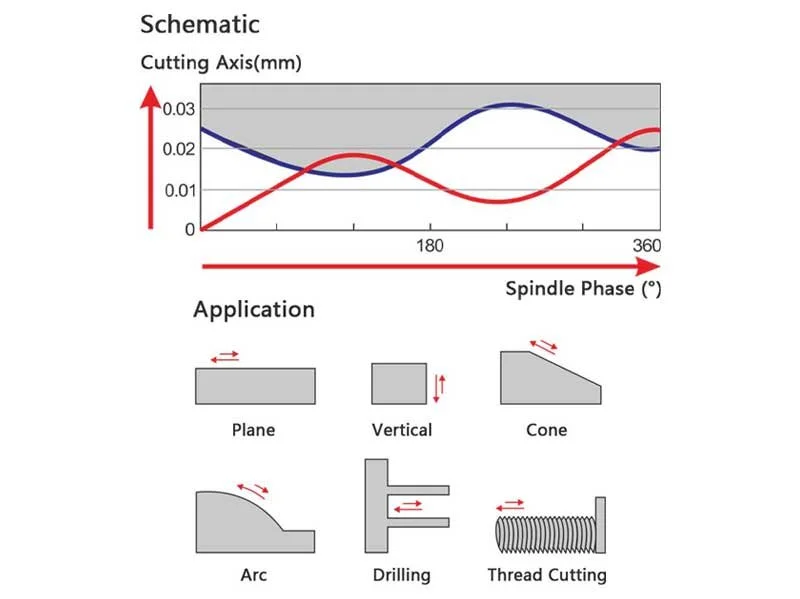

Chip Breaking Function

The "full synchronization" chip breaking technology effectively meets the technical requirements for chip breaking in turning operations at a low cost. It ensures consistent chip breaking across different spindle speeds, significantly reducing or even eliminating the need for manual intervention. Additionally, it guarantees superior surface cutting quality and enhances machining efficiency.

-

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Programmable-Servo-Tailstock-Function]()

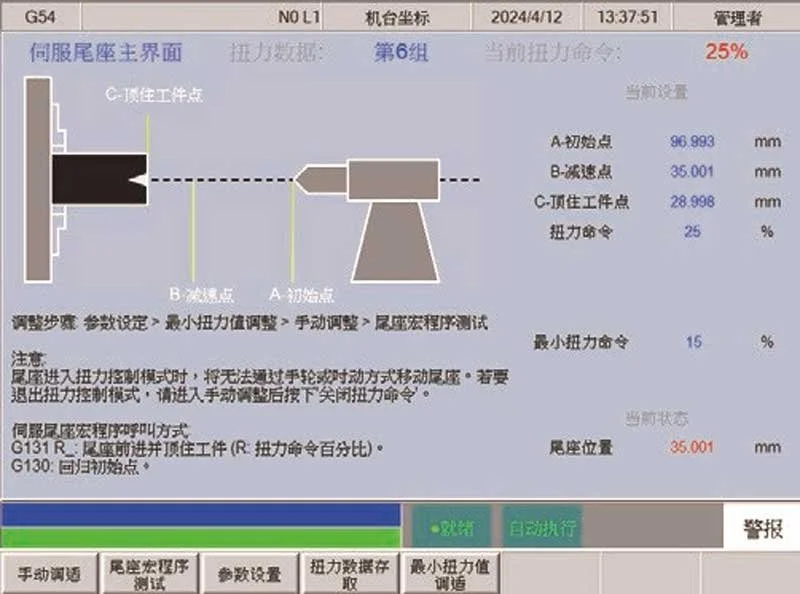

Programmable Servo Tailstock Function

Unlike traditional hydraulic tailstocks, the programmable servo tailstock allows flexible definition of clamping positions through programming. It also enables precise torque control by specifying the clamping torque value using segmented torque commands, providing enhanced flexibility and precision.

-

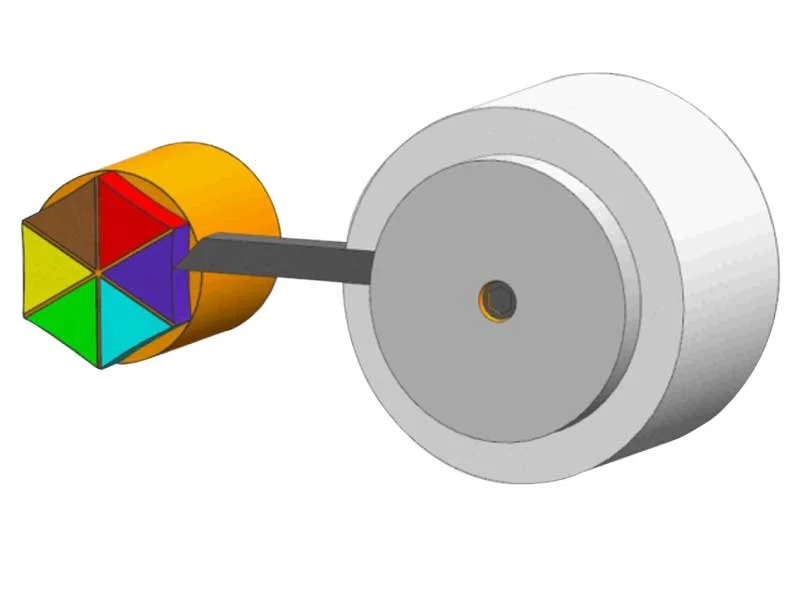

![Smartlathe-cnc-lathe-smartbrain-cnc-control-system-Polygon-Turning]()

Polygon Turning

Multi-spindle systems enable rapid turning of polygonal shapes with automatic spindle phase synchronization. The closed-loop control ensures the spindle phase remains accurate without loss, allowing for repeated polygonal machining even after program interruptions.

-

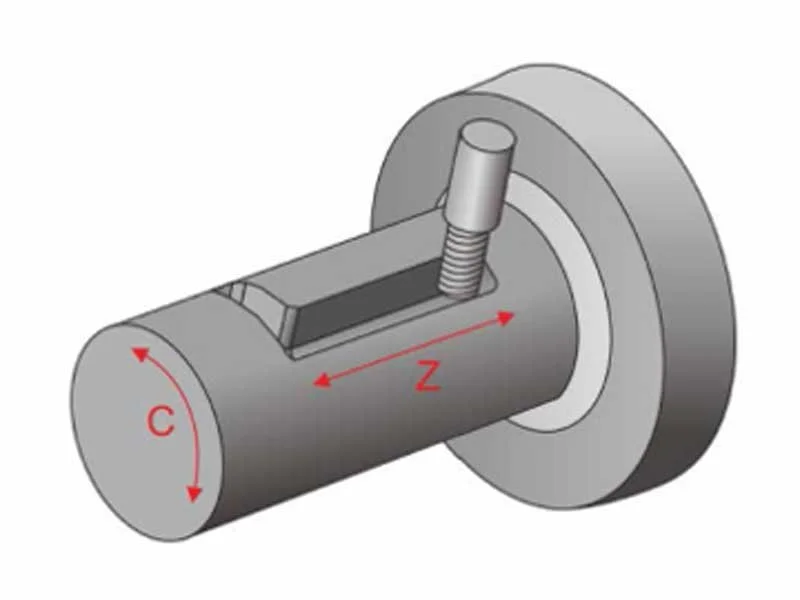

![Smartlathe-cnc-lathe-smartbrain-cnc-control-system-Cylindrical-Interpolation-Function]()

Cylindrical Interpolation Function

The system converts the rotational axis movement specified by angular commands into linear distances on the cylindrical surface. This facilitates seamless linear or circular interpolation with other axes and significantly simplifies programming for cylindrical surface machining.

-

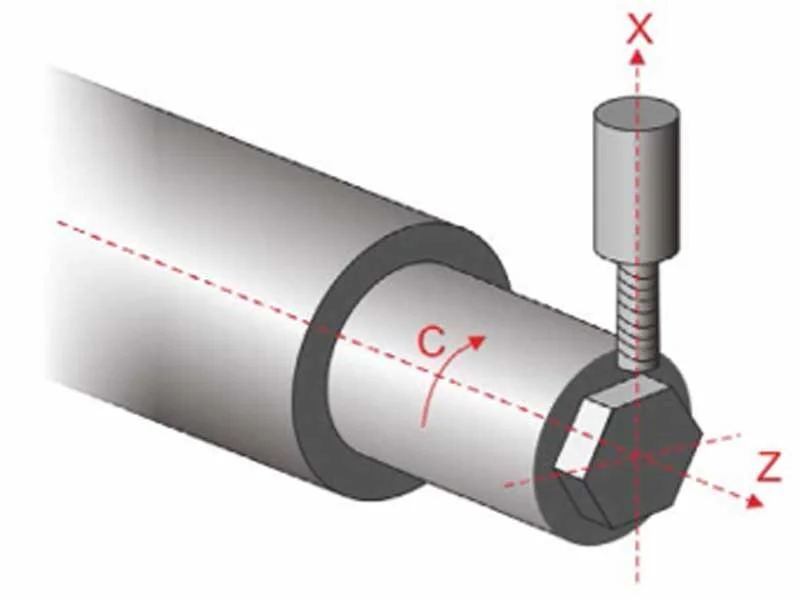

![Smartlathe-cnc-lathe-smartbrain-cnc-control-system-Polar-Coordinate-Interpolation]()

Polar Coordinate Interpolation

This function enables contour control by using Cartesian coordinate commands to interpolate the linear and rotational axes. It is ideal for applications such as cam machining, sharp turning of workpiece external diameters, and mirror finishing of irregular workpieces.

-

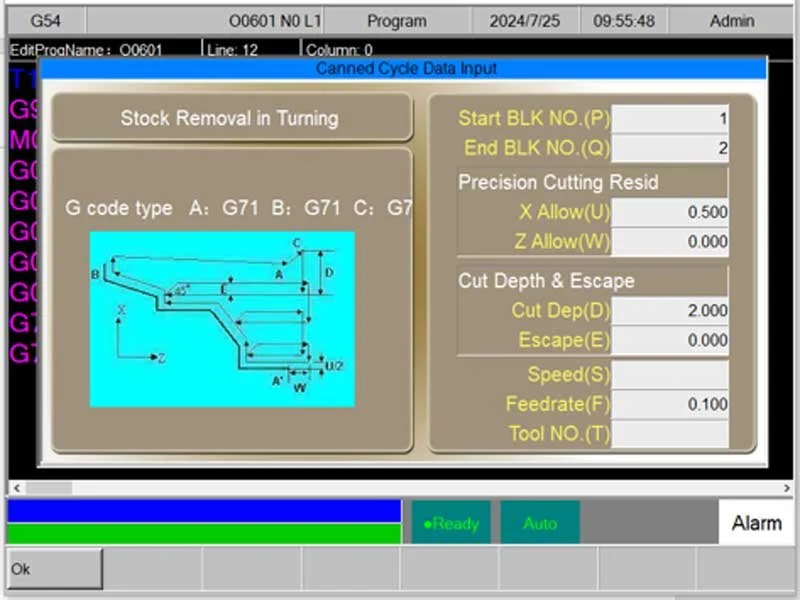

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Grooving-Path-Machining]()

Grooving Path Machining

The G71/G72 commands enable automatic rough and finish cycles for grooving path machining. This simplifies programming complexity and makes operation more convenient and efficient.

-

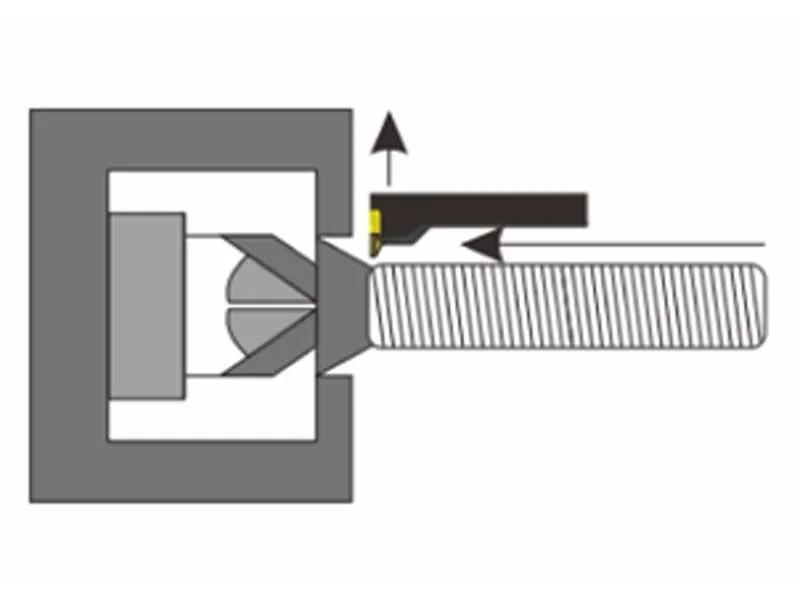

![Smartlathe-cnc-lathe-smartbrain-cnc-control-system-Quick-Thread-Exit]()

Quick Thread Exit

This function allows the tool to retract at maximum speed at the thread exit point, minimizing inaccuracies in the thread pitch at the exit and enhancing the precision of thread machining.

-

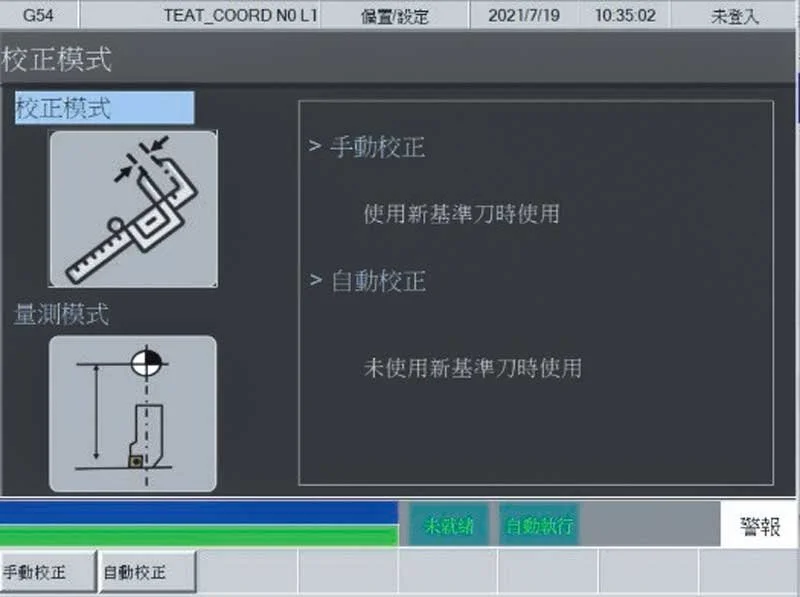

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Tool-setting-probe-page]()

Tool setting probe page

The Syntec 22TB control system features a dedicated tool setter page designed to improve tool measurement accuracy and machining efficiency. This intuitive interface allows users to set tools quickly and precisely, minimizing manual errors and enhancing production consistency.

-

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Graphic-Input-Assistance]()

Graphic Input Assistance

Syntec Graphic Input Assistance simplifies CNC programming by providing an intuitive, visual interface. This feature enables operators to input machining parameters easily without requiring complex G-code knowledge, making the system more user-friendly and efficient.

-

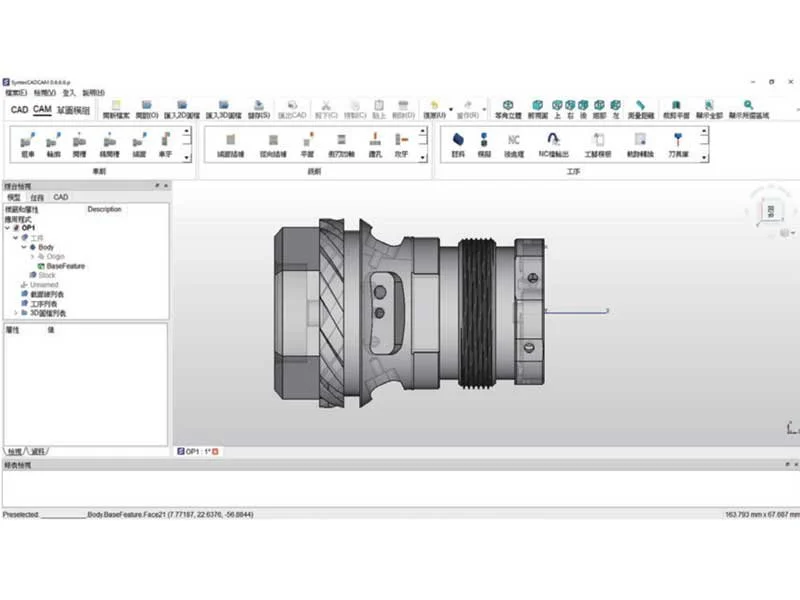

![Smartlathe-cnc-lathe-syntec-cnc-control-system-Syntec-CAD-CAM]()

Syntec CAD/CAM

Syntec’s CAD/CAM software enhances the efficiency and precision of CNC machining on the 22TB control system. By integrating design and programming, it enables seamless workflow from drawing to machining, reducing manual input and improving production accuracy.