FANUC

FANUC series oi-TF Plus

|

Control method |

Bus control |

|

Use type |

Turn-milling lathe with Y-AXIS |

|

Number of input and output |

32 IN/32 OUT |

|

Number of linkage axes |

4(XYZC) |

|

Applicable models |

SL-X/SL-52YT/ST-series/DS-series |

Special Features

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Fast-Cycle-time-Technology]()

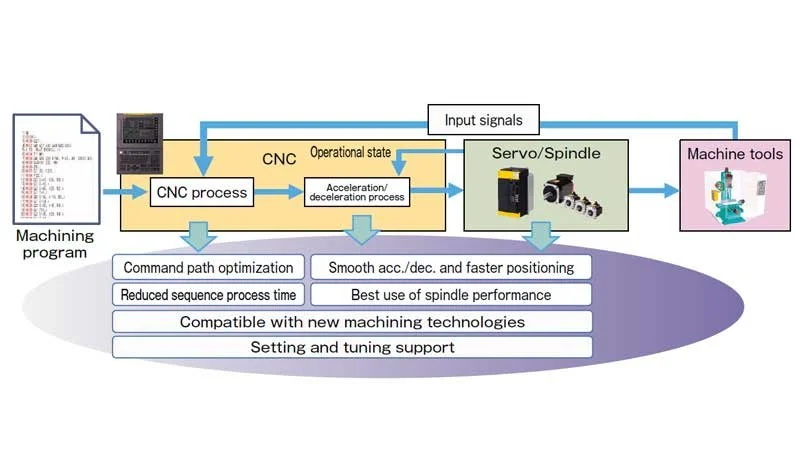

Fast Cycle-time Technology

Fast Cycle Time Technology refers to CNC and servo technologies that achieve reduced cycle times. It reduces cycle times of machining programs through methods such as accelerating and decelerating depending on the operational state, making the best use of spindle performance, and reducing the sequence processing time for external signals.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Fine-Surface-Technology]()

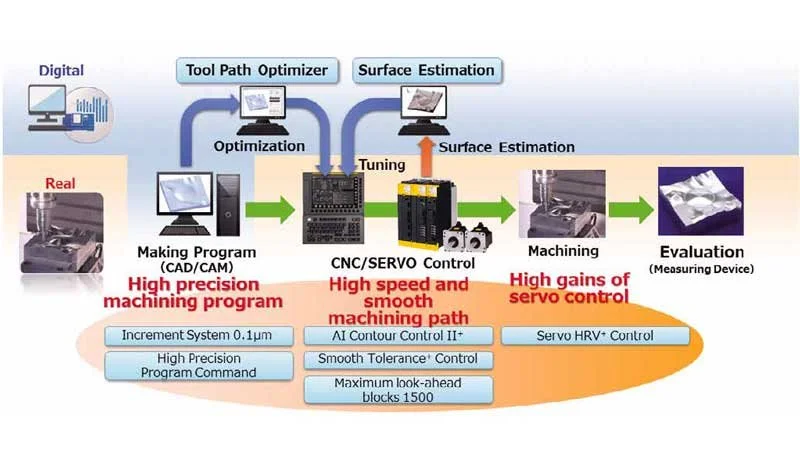

Fine Surface Technology

Fine Surface Technology is a collective term for CNC and servo technologies that achieve fine surface machining. This technology allows for the interpolation of high precision machining program output from CAD/CAM, high-speed execution of small segment programs, the generation of a smooth tool path and accurate command follow-up. These tasks more efficiently by taking digital technology.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Smooth-Tolerance-and-Control]()

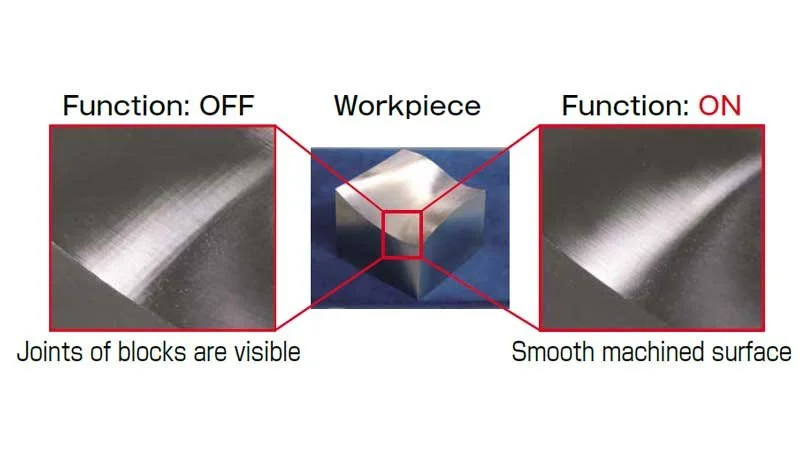

Smooth Tolerance & Control

Smoothing continuous small blocks to realize fine surface machining. The machining path specified in continuous small blocks, like the one for mold machining, is smoothed out within the specified allowance error tolerance. The smooth machining path reduces mechanical shock and improves the quality of the machined surface.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Servo-Learning-Oscillation]()

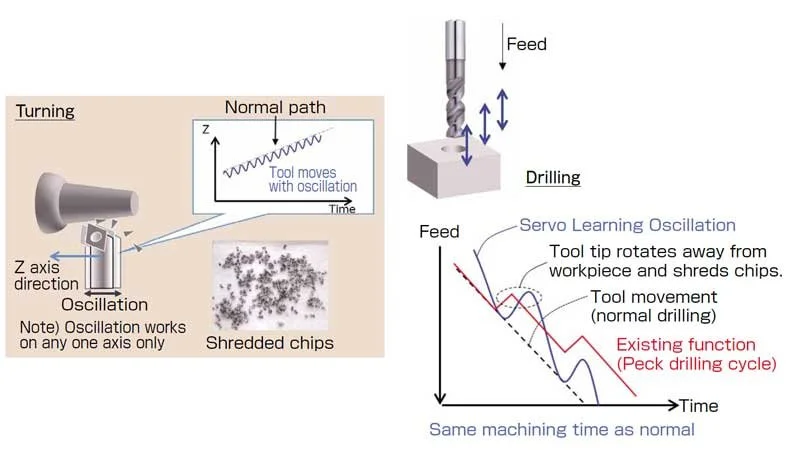

Servo Learning Oscillation

Servo learning oscillation that applies servo learning control also accurately tracks oscillation commands with a high frequency, there by achieving dependable chip shredding. It can be applied to turning, drilling and threading.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Smart-Servo-Control]()

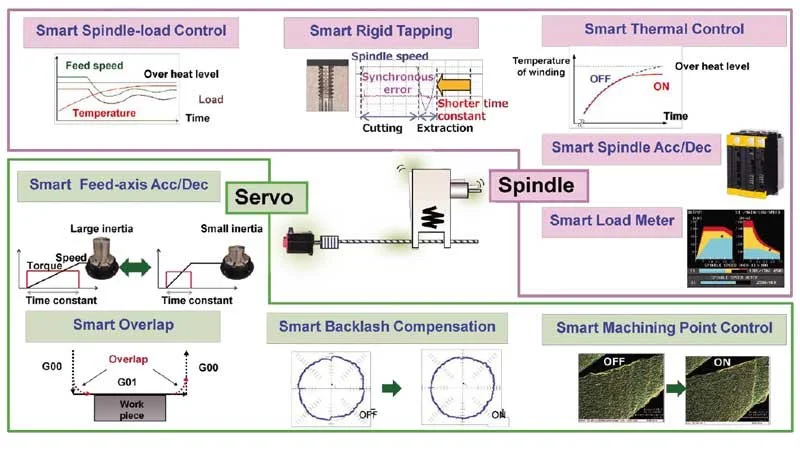

Smart Servo Control

Smart Servo Control is a group of functions to optimize control in real time according to the change of machine conditions such as load and temperature. These functions contribute to high-speed, high-precision and high-quality machining as the control technology supporting Fast Cycle-time Technology and Fine Surace Technology.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Set-up-Guidance-Function]()

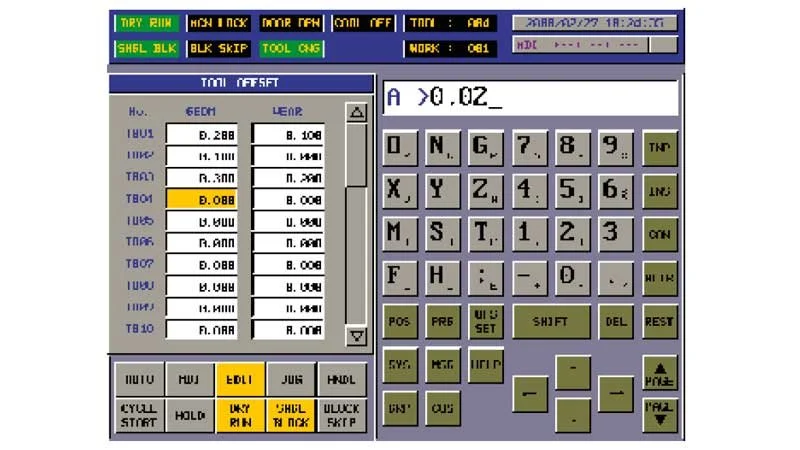

Set-up Guidance Function

Measurement is achieved by touching the tool to the work manually. And the measurement value can be set to the work coordinate system. As a result, the arrangements time can be greatly reduced.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-C-Language-Executor]()

C Language Executor

Machine tool builders can create their own operation screens, which enables unique CNC display and operation

· C language is used for programming.

· Multi window display enables creation of pop-up menus.

· Operation screens using the touch panel can be created.

· In addition to standard ANSl functions, many functions are available for CNCs and PMCs.

· High-level tasks to which high execution priority is assigned can monitor signal and position information.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Easy-Robots-Connection-and-Control]()

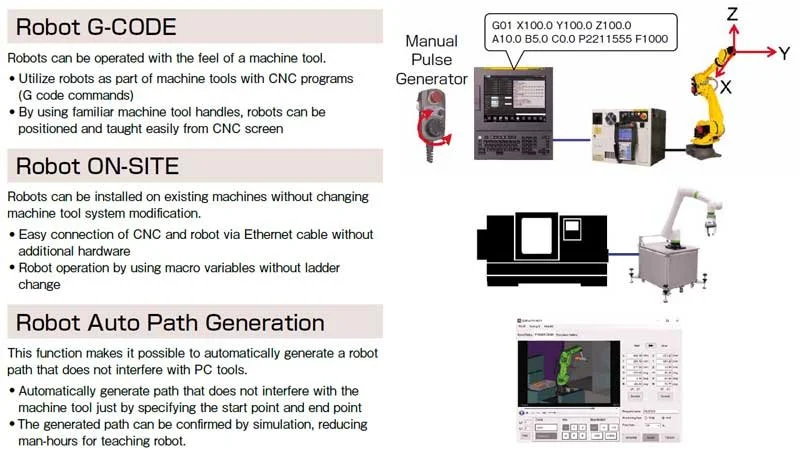

Easy Robots Connection and Control

This function allows you to easily connect a FANUC robot to a machine tool. Machine users with no experience using robots will be able to use robots easily.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Network-Support-Functions]()

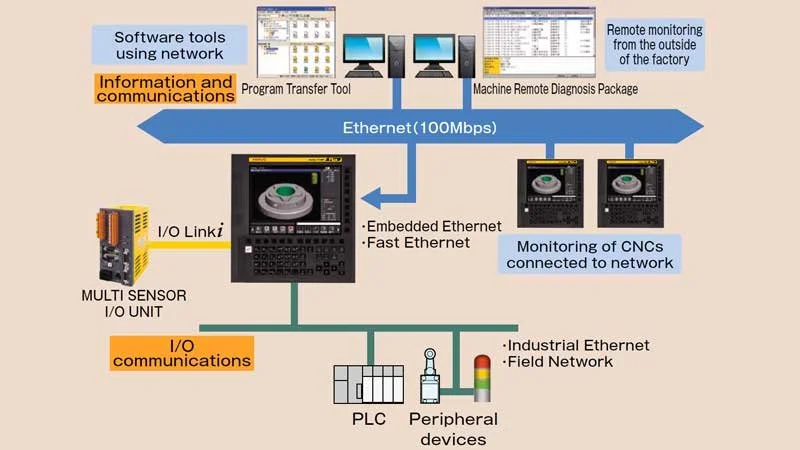

Network Support Functions

You can use Embedded Ethernet provided as standard and Fast Ethernet with a communication dedicated processor for NC program transfer and remote maintenance.

Various types of Industrial Ethernet and Field Networks are supported to enable various types of peripheral devices to be connected for controlling peripheral devices, such as waterproof I/O devices and collecting sensor information. Via a MULTI SENSOR I/O UNIT or other devices, information of impact, temperature, and other sensors can also be read.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-FANUC-MT-LINK1(Operation-Management-software)]()

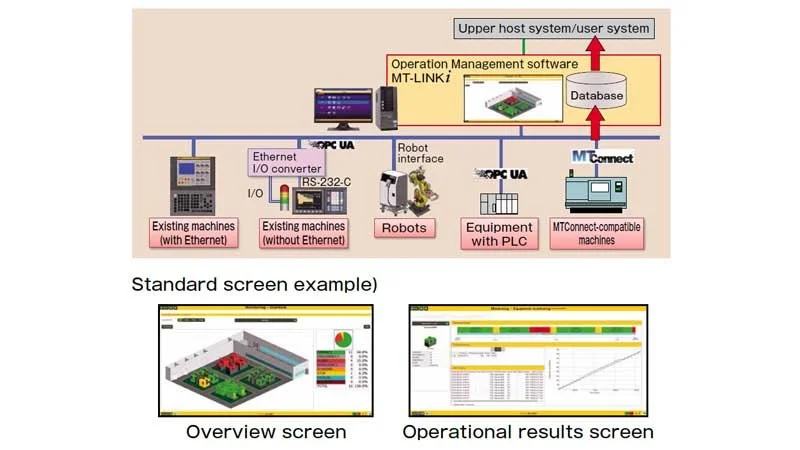

FANUC MT-LINK1(Operation Management software)

MT-LINKi is a software product that can collect, manage, and help visualize various information of machines connected via Ethernet. lt helps visualize the machines in factories, and contributes to minimizing downtime.

· It can collect device information not only from machine tools equipped with FANUC CNCs, but also from FANUC robot controllers, OPC-compatible PLCs, and MTConnect-compatible machine tools.

· Information of existing devices that do not have Ethernet l/F can also be collected by using an Ethernet I/O converter.

· Many standard screens that display various pieces of information such as the operational results of machines are available.

-

![Smartlathe-cnc-lathe-fanuc-cnc-control-system-Visualization-of-machine-operation]()

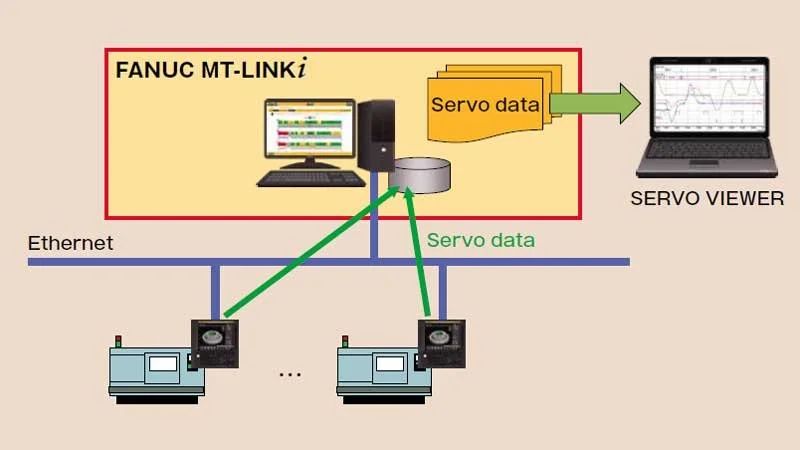

Visualization of machine operation

By using MT-LINKi together with SERVO VIEWER, servo data and various status signals are collected, achieving the visualization of detailed machine operations.

· High-speed sampling (1ms) servo data is efficiently collected from multiple machine tools.

· Various schedule and trigger functions enable efficient analyses by collecting only required data at the right timing.