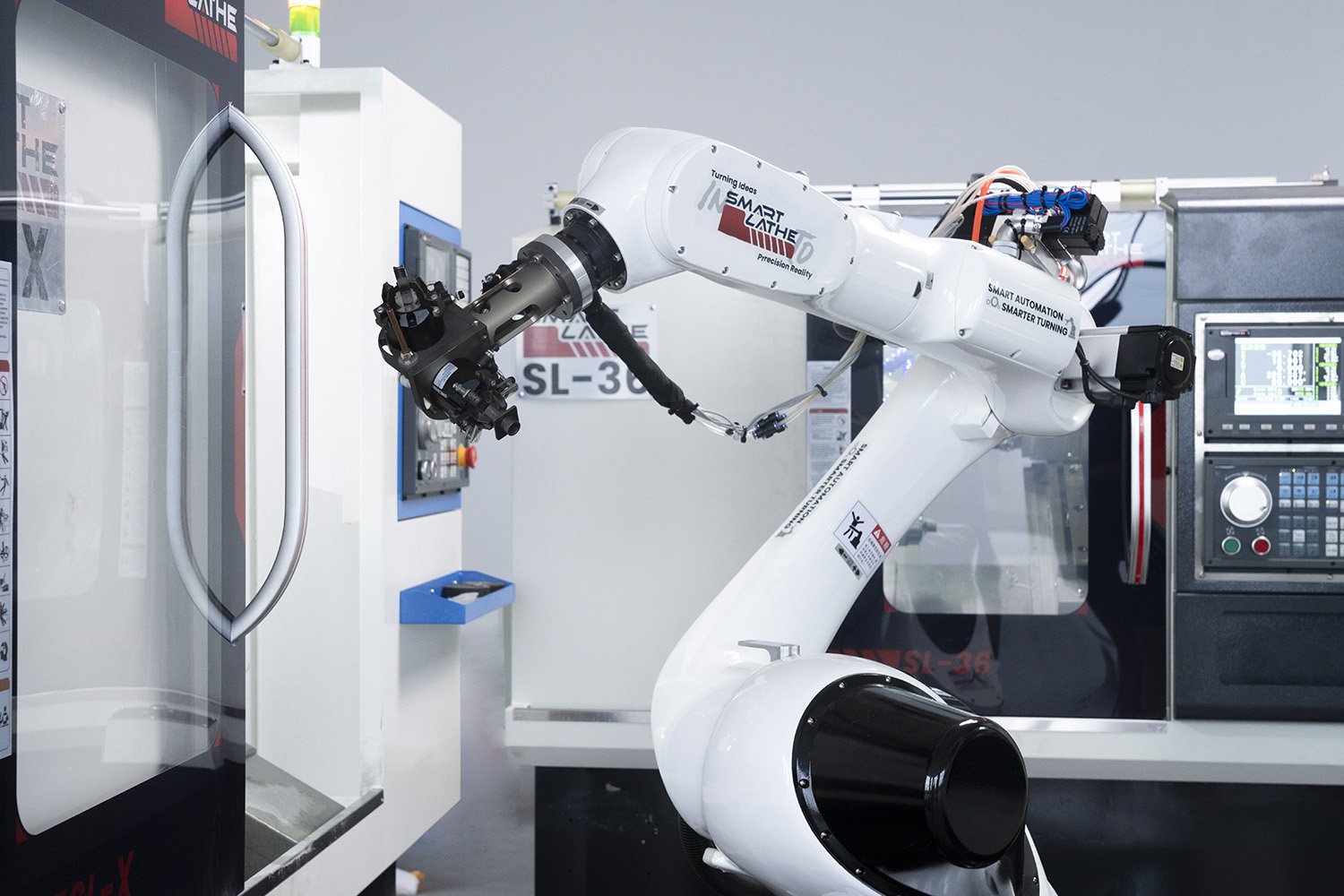

Application of Automated Robotic Arms in CNC Lathes

With the rapid advancement of technology, automation is increasingly being applied in the manufacturing industry. As a crucial component of this trend, the use of automated robotic arms in CNC lathes not only enhances production efficiency but also improves the precision and quality of products. This article will explore the application of automated robotic arms in CNC lathes and the numerous advantages they offer.

1.Advantages of Automated Robotic Arms

Automated robotic arms offer numerous benefits in modern CNC lathe production. Here, we will briefly introduce some of these advantages:

Increased Production Efficiency: Robotic arms can operate 24/7, significantly boosting production efficiency. Especially in mass production, the high-efficiency operation of robotic arms greatly reduces production cycles.

Ensured Processing Precision: Robotic arms can operate precisely according to set programs, avoiding errors that may occur with manual operations, thereby ensuring the precision and consistency of products.

Reduced Labor Costs: The application of automated robotic arms reduces reliance on manual operations, decreasing labor intensity and costs. Moreover, companies can reallocate human resources to positions requiring more creativity and judgment, enhancing overall work efficiency.

Enhanced Safety: Robotic arms can operate in hazardous environments, such as those involving high temperatures, high pressure, or toxic conditions, replacing manual labor. This greatly enhances production safety and reduces workplace accidents.

Realization of Smart Manufacturing: By integrating with CNC systems, robotic arms can achieve intelligent control and data collection, forming a smart manufacturing system and further promoting the transition of factories towards intelligent manufacturing.

2.Application of Automated Robotic Arms in CNC Lathes

Automated robotic arms simulate human hand movements and can perform various complex tasks through programmed control. In CNC lathes, robotic arms can achieve the following tasks:

Loading and Unloading of Workpieces: Robotic arms can automatically complete the loading and unloading of workpieces, reducing manual intervention and increasing production efficiency.

Transfer and Placement of Workpieces: In multi-process machining, robotic arms can accurately transfer workpieces from one station to another, ensuring continuity and accuracy in the machining process.

Quality Inspection and Sorting: Robotic arms, in conjunction with sensors and inspection equipment, can perform online inspections of workpieces and classify and sort them based on inspection results.

Smartlathe, through technical analysis, has preliminarily provided different automation solutions for CNC lathes using robotic arms. In the near future, it will offer various design and deployment plans. Stay tuned for updates.