Differences in programming between Fanuc and GSK

G-code Compatibility

Both systems support ISO standard G-codes such as G01, G02, G03, etc. The basic programming logic is similar.

| Fanuc | GSK |

| % O1001 M22 G21 G18 G40 M97 G80 G99 M64 N1(1) G0 G28 A0. G28 U0. V0. G28 W0. M141 M74 G54 G99 G18 M75 T0202 M16 M8 G97 S3000 M3 P11 G0 Z66. X50. Y0. Z1.9 X4.616 G1 X4.601 Z-0.1 F0.15 G3 X7. Z-1.299 R1.204 F0.1 G1 Z-1.3 Z-5.119 G3 X28.601 Z-18.574 R12.2 X20.363 Z-26.451 R12.2 G1 X9.981 Z-30.987 G2 X27.414 Z-44.893 R13.3 G3 X29. Z-46.022 R1.2 G1 Z-47.854 Z-47.858 G3 X28.055 Z-48.835 R1.355 G2 X28.314 Z-51.91 R2.3 G3 X29. Z-52.749 R1.2 G1 Z-57.3 X33. F0.15 G0 X50. Z66. M5 P11 M9 M65 G0 G28 A0. G28 U0. V0. G28 W0. M75 M30 % |

O1001 G00 G40 G80 G21 N1(1) G28 W0. M21 G54 M15 G99 G18 T0202 M08 G97 S3000 M03 G00 Z66. X50. Z1.9 X4.616 G01 X4.601 Z-0.1 F0.15 G03 X7. Z-1.299 R1.204 F0.1 G01 Z-1.3 Z-5.119 G03 X28.602 Z-18.574 R12.2 X20.364 Z-26.451 R12.2 G01 X9.981 Z-30.987 G02 X27.414 Z-44.892 R13.3 G03 X29. Z-46.022 R1.2 G01 Z-47.854 Z-47.858 G03 X28.054 Z-48.834 R1.355 G02 X28.314 Z-51.91 R2.3 G03 X29. Z-52.749 R1.2 G01 Z-57.3 X33. F0.15 G00 X50. Z66. M05 M09 G28 W0. M15 M30 |

We used post-processing in Fusion 360 to generate turn-mill programs for both GSK and Fanuc systems.

Support for Thread Cutting and Rigid Tapping

Both systems support threading and rigid tapping, and can handle various thread types (metric, imperial, tapered threads, etc.).

|

FANUC |

GSK |

|

T5; (Select tapping tool ) |

T5; (Select tapping tool ) |

|

M29S500P1 (Set spindle speed to 500 rpm, select main spindle 1 ) |

M03 (Select main spindle 1) |

|

G00 X0 Y0; (Rapid move to tapping position ) |

M29S500 (Set spindle speed to 500 rpm) |

|

M08; (Coolant on ) |

G00 X0 Y0; (Rapid move to tapping position ) |

|

G84 G99 Z-20.0 R1.0 F1.25; (Tapping cycle, feed 1.25 mm/rev ) |

M08; (Coolant on ) |

|

G80; (Cancel fixed cycle ) |

G84 G99 Z-20.0 R1.0 F1.25; (Tapping cycle, feed 1.25 mm/rev ) |

|

M09; (Coolant off ) |

G80; (Cancel fixed cycle ) |

|

|

M09; (Coolant off ) |

Macro Program Support

Both systems support user-defined macro programs (such as FANUC’s Macro B and GSK’s user macros), enabling parametric programming.

|

Comparison Item |

FANUC |

GSK |

|

Variable naming |

User variables start from #100 |

User variables start from #500 |

|

System variables |

FANUC-specific, e.g., #5001 for current X-axis position |

GSK-specific, e.g., #4001 for current X-axis position |

|

Assignment |

#100 = 20 |

#500 = 20 |

|

Operators |

+ - * / MOD |

+ - * / MOD(same) |

|

Conditional statements |

IF [#100 EQ 10] GOTO 100 |

IF [#500 EQ 10] GOTO 100(same) |

|

Loop control |

WHILE [#100 LT 10] DO1 ... END1 |

WHILE [#500 LT 10] DO1 ... END1(same) |

|

Subprogram call |

M98P1000 |

M98P1000(same) |

|

Return to main program |

M99 |

M99(same) |

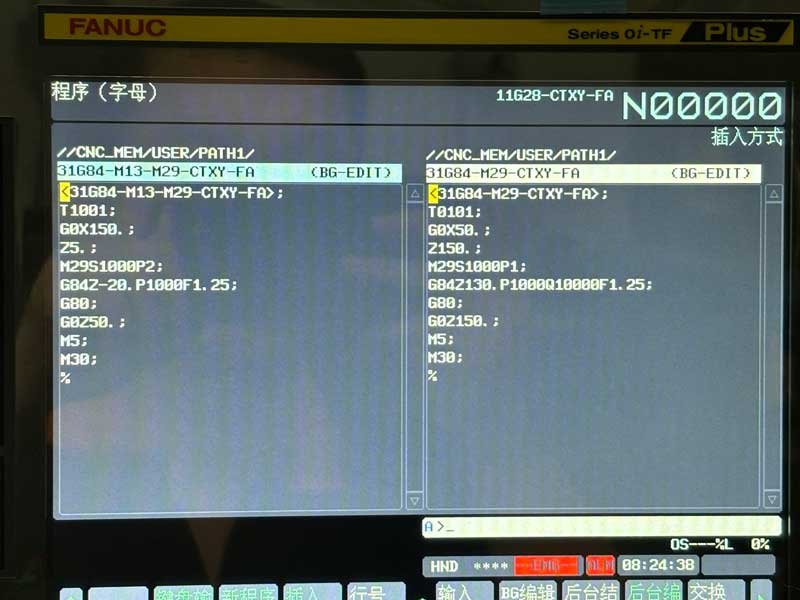

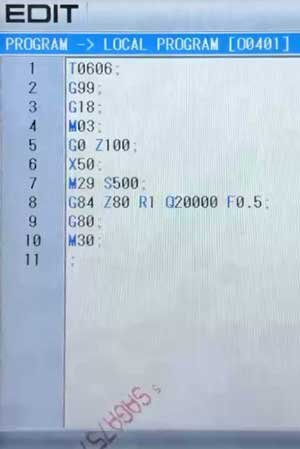

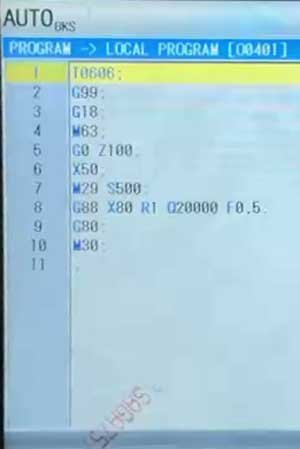

Testing

We ran a tapping program originally used on the FANUC system on the GSK system.

Fanuc Living tools tapping and Spindle tapping

GSK Spindle tapping

GSK Living tools tapping