The Impact of Spindle Speed and Feed Rate on Chip Formation

In the world of CNC lathe, chip formation is a crucial indicator. It directly affects machining efficiency, tool life, and the quality of the finished product. When delving into chip formation, two critical factors come to the forefront: spindle speed and feed rate.

1.Spindle Speed

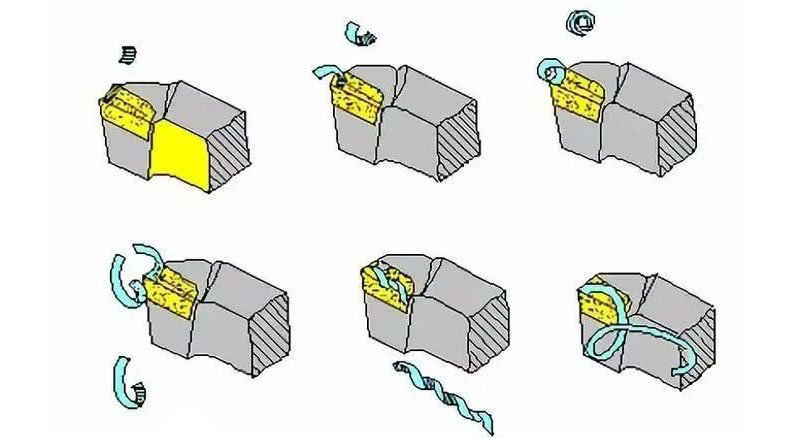

The spindle speed in CNC lathes is an important parameter that influences chip formation. Increasing the spindle speed raises the cutting temperature, causing the chips to soften and form serrated shapes. Additionally, higher spindle speeds reduce cutting forces because the increased cutting speed decreases the friction between the chip and the tool's rake face. However, in some cases, the spindle speed's impact on chip formation might not be evident. This could be due to other parameters, such as feed rate, overshadowing the changes caused by spindle speed.

2.Feed Rate

The feed rate of the cutting tool has a direct impact on chip formation. Increasing the feed rate increases the cutting thickness, affecting the chip's thickness and rigidity, thereby influencing the chip's fracture behavior. When the feed rate is low, the chip deformation increases, potentially making chip breakage difficult. Higher feed rates can also lead to increased cutting forces, particularly tangential cutting force. In low-feed grooving operations, reducing the feed rate can decrease cutting force and surface residual height, improving machining accuracy, but it may also make chip breaking challenging.

3.Combined Influence

Spindle speed and feed rate together determine the chip formation and fracture mechanism. So, how should one select the appropriate spindle speed and feed rate in practical machining? This decision should be based on the specific machining material and tool parameters. Generally, harder materials require higher spindle speeds and appropriate feed rates to ensure effective cutting. Conversely, softer materials can benefit from reduced spindle speeds and feed rates to enhance machining efficiency.

Additionally, the tool's material and geometry significantly influence cutting performance. For instance, carbide tools are suitable for high-speed cutting, whereas high-speed steel tools are better suited for low-speed cutting. The tool's geometric parameters, such as rake angle, relief angle, and cutting edge inclination, also affect cutting forces and chip formation.

4.Practical Application

In practical operations on CNC lathes, the optimal spindle speed and feed rate can be determined through experimentation and observation. Start with a lower spindle speed and feed rate for an initial cutting test, then gradually increase these parameters, observing changes in chip formation and machining quality. When the chips are continuous, smooth, and the machining quality is satisfactory, the optimal combination of spindle speed and feed rate has likely been found.