Wedge-Type Y-Axis CNC Lathe VS Real (True) Y-Axis CNC Lathe

Mechanism:

Wedge-Type Y-Axis CNC Lathe: The wedge-type Y-axis mechanism utilizes a wedge block to position the tool off-center, enabling Y-axis movement. It allows for off-center drilling, milling, and other complex machining operations.

Real (True) Y-Axis CNC Lathe: A true Y-axis CNC lathe incorporates a dedicated Y-axis that enables vertical movement of the cutting tool perpendicular to the spindle axis. This provides precise control over the Y-axis movement and offers increased versatility in machining operations.

Flexibility and Machining Capability:

Wedge-Type Y-Axis CNC Lathe: The wedge-type Y-axis lathe offers flexibility in performing off-center machining operations. It can handle tasks like off-center drilling, milling, and other operations that require the tool to move away from the centerline of the workpiece.

Real (True) Y-Axis CNC Lathe: A true Y-axis CNC lathe provides dedicated and precise control over the Y-axis movement. It allows for a wide range of complex machining operations, including angled drilling, contouring, profiling, and other operations that require the tool to move vertically.

Complexity of Programming:

Wedge-Type Y-Axis CNC Lathe: Programming a wedge-type Y-axis lathe may require specific instructions to adjust the wedge block for off-center operations. The programming needs to account for the additional Y-axis movement.

Real (True) Y-Axis CNC Lathe: Programming a true Y-axis lathe involves straightforward instructions for the Y-axis movement, like programming the X and Z axes. It offers ease of programming for vertical tool movements.

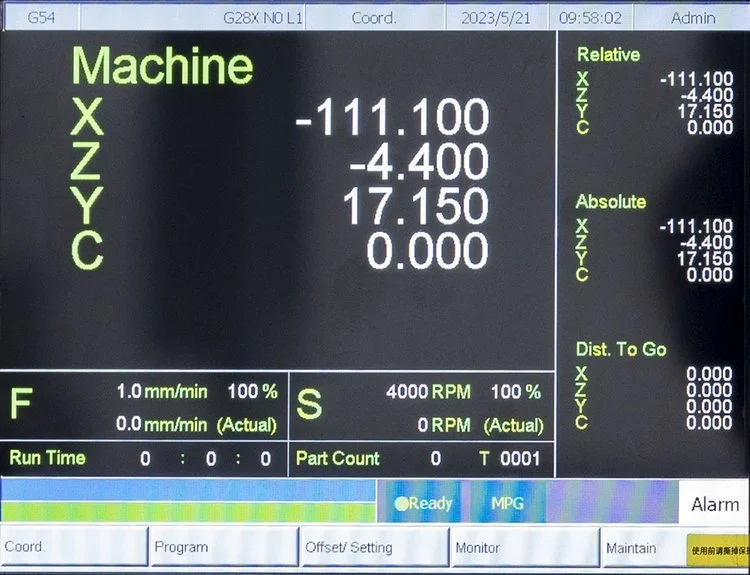

Wedge type Y-Axis programming

Real Y-Axis programming

Applications:

Wedge-Type Y-Axis CNC Lathe: The wedge-type Y-axis lathe is suitable for applications that require off-center machining, such as creating complex contours, angled features, and irregular shapes. It finds application in industries where precise off-center operations are needed.

Real (True) Y-Axis CNC Lathe: The true Y-axis lathe is versatile and can handle a wide range of machining tasks, including angled drilling, milling, profiling, and complex geometries. It is well-suited for industries that require multi-axis machining capabilities.

In summary, a wedge-type Y-axis CNC lathe offers off-center machining capabilities by utilizing a wedge block, while a real (true) Y-axis CNC lathe incorporates a dedicated Y-axis for precise vertical tool movement. The true Y-axis lathe provides enhanced versatility and ease of programming for complex machining operations, whereas the wedge-type Y-axis lathe excels in off-center operations. The choice between the two depends on the specific machining requirements and complexity of the parts being produced.