What are the main CNC machining parameters? (Turning)

CNC machining relies on precise parameter settings to ensure accuracy and repeatability. The proper setting of machining parameters determines the quality and efficiency of the machining process. These settings include spindle speed, feed rate, depth of cut and cutting tool path.

1. Turning Principle

Turning is the process of machining rotational bodies and curved surfaces using a single-point cutting tool. In most cases, the tool is fixed and performs a feed motion, while the workpiece rotates as the main movement.

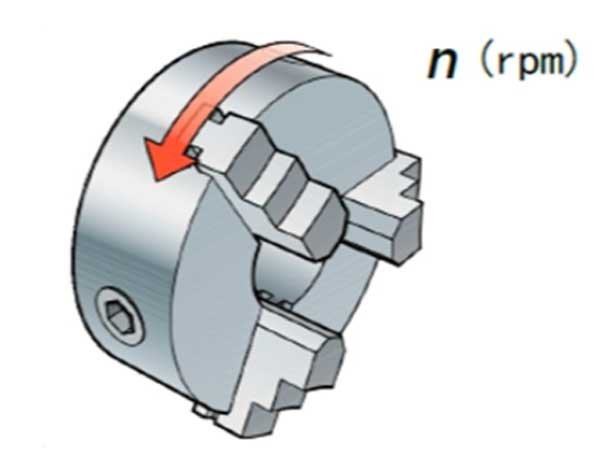

2. Spindle Speed 𝑛

The speed at which the workpiece rotates in the lathe, measured in revolutions per minute (rpm), indicating the number of rotations per minute.

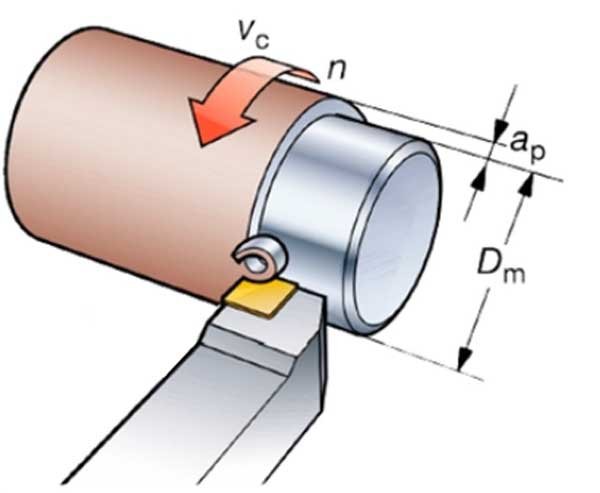

3. Line/Cutting Speed 𝑉𝑐

The cutting speed is the relative speed between the cutting tool tip and the machined surface, expressed in meters per minute (m/min).

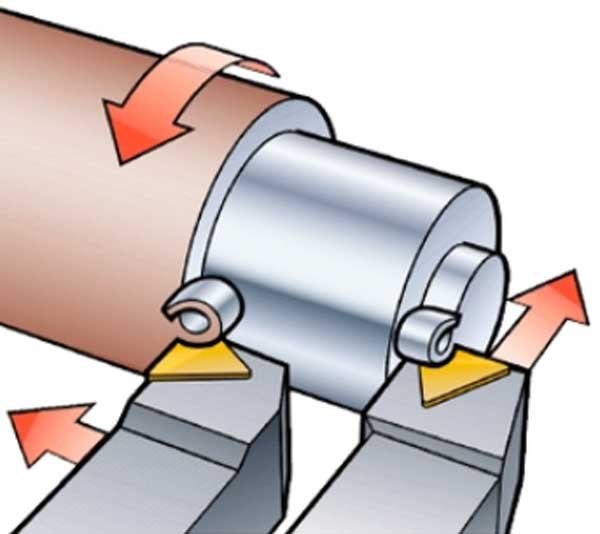

4. Feed Rate 𝑓𝑛

The feed rate is the displacement of the tool relative to the rotating workpiece per revolution, measured in millimeters per revolution (mm/r). This is a key value that determines surface finish quality and ensures the chip formation occurs within the chip groove profile of the tool. It affects both the chip thickness and the chip formation related to the tool groove geometry.

5. Cutting Depth 𝑎𝑝

The cutting depth is the amount of material removed in the radial direction per pass, measured in millimeters (mm). It is always measured perpendicular to the feed direction of the tool.

6. Main Cutting Angle 𝐾𝐴𝑃𝑅/ Entry Angle 𝑃𝑆𝐼𝑅

The proximity of the cutting edge to the workpiece is represented by the main cutting angle (KAPR), which is the angle between the cutting edge and the feed direction. The proximity can also be expressed as the entry angle (PSIR), which is the angle between the cutting edge and the workpiece plane. The main cutting angle is the primary consideration when selecting a turning tool for a specific operation.

7. Cutting Edge Length 𝐿𝐸

The cutting edge contact length is related to both the cutting depth and the main entry angle; the smaller the main angle, the longer the cutting edge contact length, resulting in a wider cut.