Choosing gang tooling or a turret for a CNC lathe

Tooling is typically installed on a gang plate or a turret for production lathes.

What Turret Lathes and Gang Tooling?

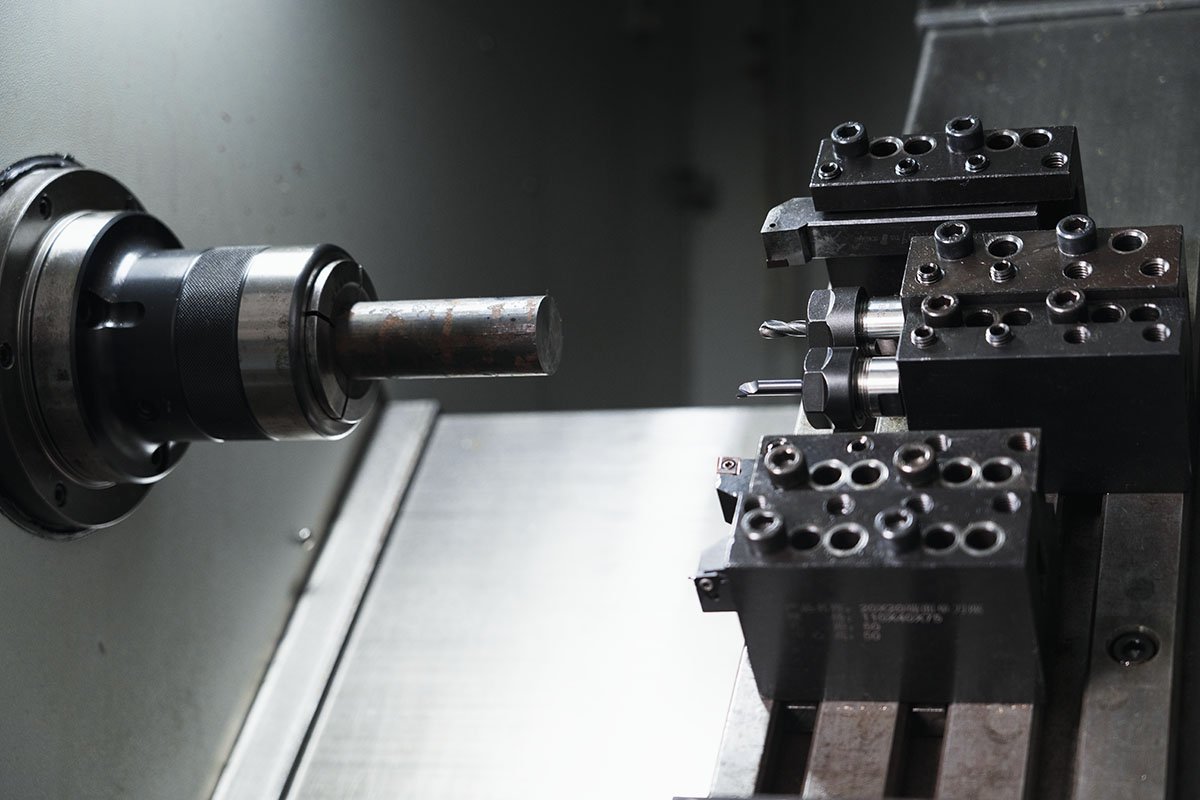

Gang tooling

The simplest solution is pure gang tooling. On the cross slide of the lathe, the tools are arranged in a row in this way. To access a tool, move away from the workpiece along the spindle axis to prevent the tools from striking the workpiece, slide the X axis until the right tool is in place, and then move away from the workpiece along the Z axis to begin cutting.

The most straightforward solution for a CNC lathe is pure gang tooling. The cross-slide of the lathe has the tools arranged in a row. An end user follows these procedures to swap out a tool:

• Uses a Z-axis motion to pull the current tool away from the workpiece.

• Inserts X-axis slides until the new tool is in place.

•Starts cutting while moving along the Z-axis.

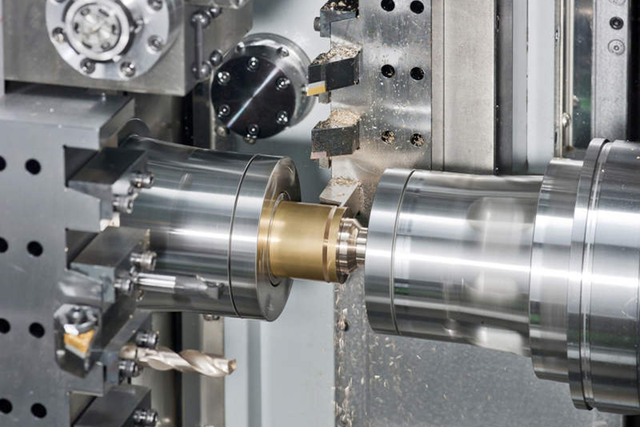

Tool turret

Additionally, larger CNC lathes and multipurpose devices frequently have turrets. Due to the lack of clearance needed under the part, turrets are recommended for major operations. Large-diameter pieces have more area since the turret can approach the part from behind.

A tool turret requires more effort than simple gang tooling. To place a new cutting tool, a turret that holds a variety of tools rotates. To replace tools, you must:

• Removing the present tool from the workpiece, often using a Z-axis motion or an X-Z motion combined.

• Rotating the turret to position the proper tool.

• Moving the tool forward once more in a Z or XZ motion to start cutting.

Which one is better?

|

Turret pros |

Gang pros |

|

More flexible |

Faster tool changes |

|

Handles longer, skinnier parts |

Simpler |

|

Handles larger diameter parts |

Lower cost |

|

Easier to program |

Faster setup |

|

Accommodates more tools |

More accurate |

|

More possible axes |

More Reliable |

Here’s the top-level conclusion:

Depending on the kind of items being machined, a CNC lathe should use gang tooling or a turret:

• Gang tooling is particularly difficult to beat for short, thin pieces without a need for a tailstock.

• Turrets offer greater versatility. For long, slender sections that require a tailstock for support, they are a necessity.

Many machinists use turret machines for items that are too long and thin to be manufactured on gang lathes, despite the fact that they would want to be able to utilize gang lathes for everything.

We'll get to a lengthy list of benefits and drawbacks for each in a moment, but as promised, let's start with the broad conclusion.

What kind of parts you'll be producing ultimately determines whether you use gang tooling or turrets on a CNC lathe. For shorter items with a lower diameter and no need for a tailstock, gang tooling is very difficult to surpass. When you need a tailstock for your part, a turret lathe is unbeatable for adaptability and a necessity.

I frequently came across machinists using turret lathes for pieces that were too long and thin to be created with a gang lathe when reading through the several publications I read about the subject.

WHAT IS ADVANTAGE OF GANG TOOLING AND TURRET LAHTE

A Swiss machine can turn items that would be too long and spindly to do with a Gang Lathe, but at the expense of greater expense, complexity, and the requirement of barstock that is more expensive since it must be compatible with the Swiss bushing configuration.

Gang Tooling Advantage #1: Speed

The gang tool change is super fast because it uses slide motion to do toolchanges and requires no turret indexing.

Gang Tooling Advantage #2: Simplicity and Low Cost

All of the work for a toolchange is done by the lathe's standard axis servos and leadscrews. As a result, gang lathes can frequently be far less expensive than turret lathes.

Due to the challenges of delivering rotating power to the tool positions on a rotary turret, motorizing a turret raises the cost in numerous ways.

Gang Tooling Advantage #3: Fast Setup

With a modest set of tools and, for instance, by simply switching out one block that houses a specific size twist drill, a great deal of gang work can be accomplished.

Gang Tooling Advantage #4: Accuracy

The moving parts of a turret's moving parts are made simpler and have fewer moving parts, which avoids tolerance stack up and different types of slop (backlash).

The gang lathe also has an accuracy advantage because it is accustomed to moving a part across shorter distances.

Gang Tooling Advantage #5: Robustness

This one has a direct connection to simplicity. A gang lathe is not prone to many errors.

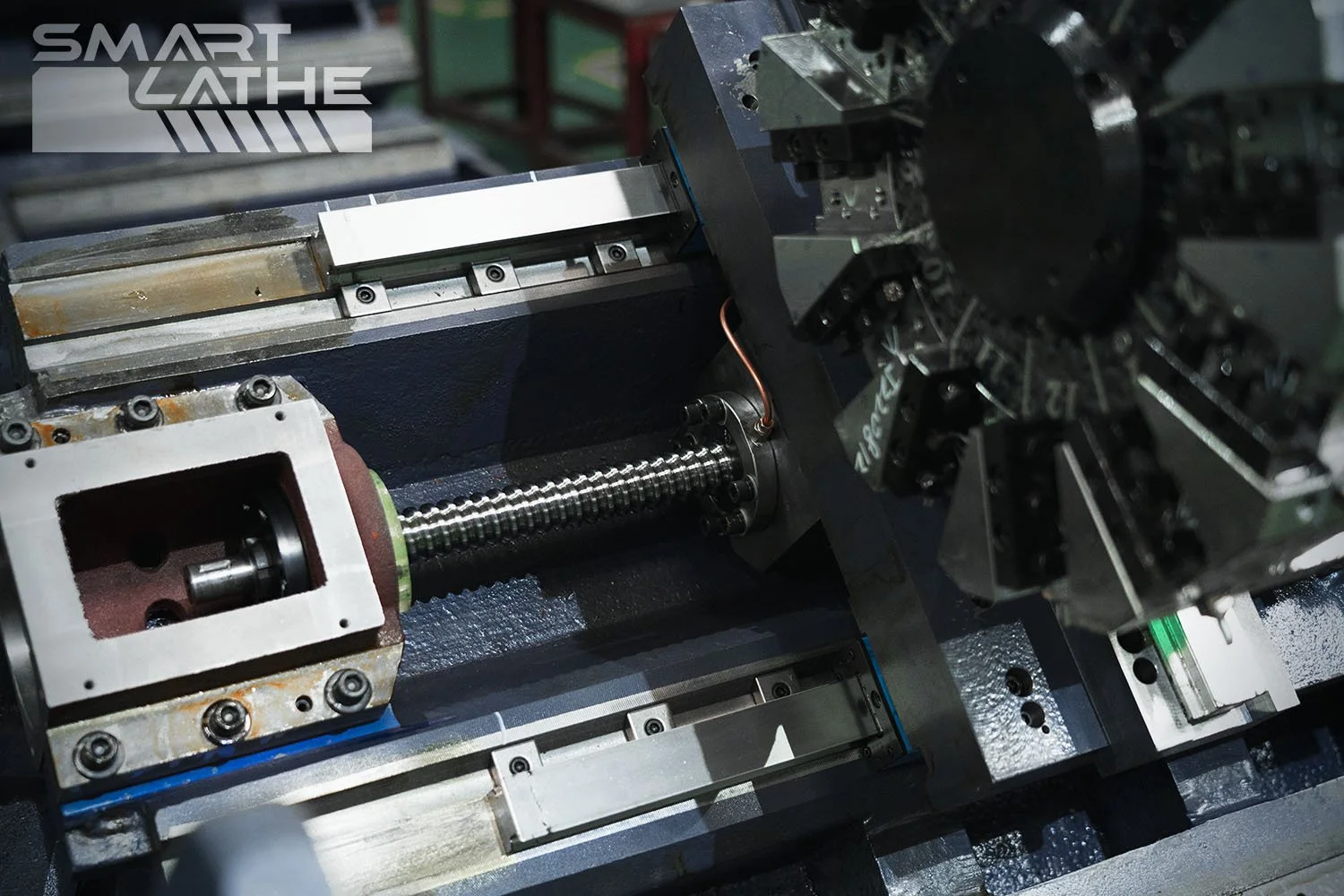

Turret Lathe Advantage #1: Flexibility

Flexibility is a Turret's top benefit. With one, you can use a tailstock, allowing you to make pieces that are considerably longer and more slender than you could with a gang lathe.

Turret Lathe Advantage #2: Easier Programming

Since the tools are on either side of the workpiece, gang members must contend with the idea of both positive and negative. Users of turrets only have to deal with one sign, and they typically choose the positive option since it is easier to understand.

Turret Lathe Advantage #3: More Tools

Having two turrets, or even just putting gang holders in a few turret stations, means more tools for the turret lathe.

Turret Lathe Advantage #4: More Operations, Axes, and Parts Complexity

This one relates to the Turrets' flexibility benefit, although they appear to work best with more complicated machines that are equipped with dual spindles, multiple axes, and other characteristics to handle components that would otherwise require numerous setups.

Turret Lathe Advantage #5: Better Hogging?

Turrets are more common on larger lathes, which alone can lead to better hogging.

Conclusion:

The easiest way to decide between gang tooling and turret lathes is to carefully consider the kinds of parts that will be created and the advantages those particular parts will gain.

You will probably prefer a Turret if you are unsure of the kind of parts you will eventually produce and are unwilling to accept the restrictions of gang tooling to smaller diameter shorter items. The turret lathe is probably what you want if you want the smallest learning curve and the easiest programming imaginable. On the other hand, gang tooling is a good option if you want the quickest cycle times so you can produce as many of the parts created on gang lathes as possible at a low cost.