Knowledge about Dual Spindle CNC Lathe

We continue to invent and develop new technologies in the field of CNC lathes in order to offer greater quality and productivity. The definition of a dual-spindle CNC lathe will next be explained.

What is a dual- spindle lathe?

Dual-spindle lathes are typically defined as having a main spindle and a secondary spindle with identical chuck size and through-bore capacity, but with different horsepower. two spindles. There are different types of two-spindle machines. In one style, the spindles face each other, and in the second style they do not.

The first step in the purchasing process is frequently to simply comprehend the minute distinctions because there is so much terminology used in the industry when it comes to lathes with two spindles.The terminologies used to describe the spindle architecture inside a machine include subspindle, twin spindle, dual spindle, main spindle, and secondary spindle. Manufacturers of machine tools will use this nomenclature in a variety of ways, depending in part on the component setup and in part on personal choice.

Main spindle is the lathe's main working spindle.

Secondary spindle is frequently referred to as the pick-off spindle or back spindle and is situated to the right of the main spindle, might be superior to or equal to the main spindle.

The spindle to the right is often considered inferior to the spindle to the left when the term "Subspindle" is employed. The inferiority manifests as reduced through-bore capacity, a smaller chuck, and less horsepower. The two spindles in a Subspindle-style machine typically face one another, allowing some sort of transfer to take place between the spindles. The machine can now process parts practically continuously as a result.

Twin spindle. Both spindles in a twin-spindle configuration on a CNC lathe are typically equal in terms of their capabilities and specs.

Dual spindles. A primary spindle and a secondary spindle with the same chuck size and through-bore capacity but different horsepower are said to be dual-spindle lathes.

Two spindles. Different kinds of two-spindle machines exist. The spindles face one another in one style whereas they do not in the other. The second type needs a loading method that is either manual or gantry-style.

Benefits of Dual Spindle CNC Lathe

1) A turning center with a second spindle can improve your shop floor's productivity, cost per part, back-working capacity, and quality.

2) By automatically moving parts from one chuck to another for secondary processes, dual-spindle machines boost productivity by minimizing component handling.

3) These machines can be used in conjunction with robotic part feeding and extraction or with bar feeders for extended, unattended part runs to significantly increase productivity.

4) These machines can also produce a final component that has been machined on both faces by using secondary operations like drilling and tapping on both faces [axially] or sides [radially], among others, thanks to their part-transferring capabilities.By handling a part less frequently, part quality and consistency are also increased.

Dual Spindle CNC Lathe Work

Because the part is no longer idle while waiting for a secondary procedure to be completed, the cost per part can be decreased. The control that machinists have over the secondary spindle allows them to work on the part's reverse side. To enable back-work machining, the secondary spindle can be set to approach the item and remove it from the main chuck.

It is possible to do tasks that are typically performed by two or three machines on one, which cuts down on the time needed to thoroughly produce a given part.

Programming

The complexity of component programming changes with the addition of a second spindle to the work envelope, necessitating extra care in these circumstances.

First, the spindle rotation and toolpath orientation are switched, programming the Z axis with positive integers rather than negative ones starting from part zero.

The subspindle chuck can also be instructed to open, rotate, stop, or orient using various codes.For example, a particular controller has a special code called G14 that reverses or mirrors the entire program, so the programmer does not have to worry about programming the sub-spindle differently than the main spindle. This avoids the confusion of having to use so many different codes and numeric positioning values.

Spindle Synchronization

The DS series of our Smartlathe product is a dual-spindle CNC lathe with two spindles for simultaneous cutting and quick item transfer. Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with single workpieces up to φ240mm. High Rigidity casting iron body provides the possibility of higher hardness materials and better smoothness (smaller roughness).

Today's Dual Spindle CNC Lathes can be automated very simply, mainly because they have multiple turrets and spindles at the same time. A Dual Spindle CNC Lathe can be automated very simply by adding a bar loader and using a second spindle to finish the part.

To enable unattended machining, some sort of parts-removal device is needed to take the finished product out of the second spindle. A gantry loader can be fitted to load and unload the second spindles in the machine envelope if the component is larger than the maximum bar material size.

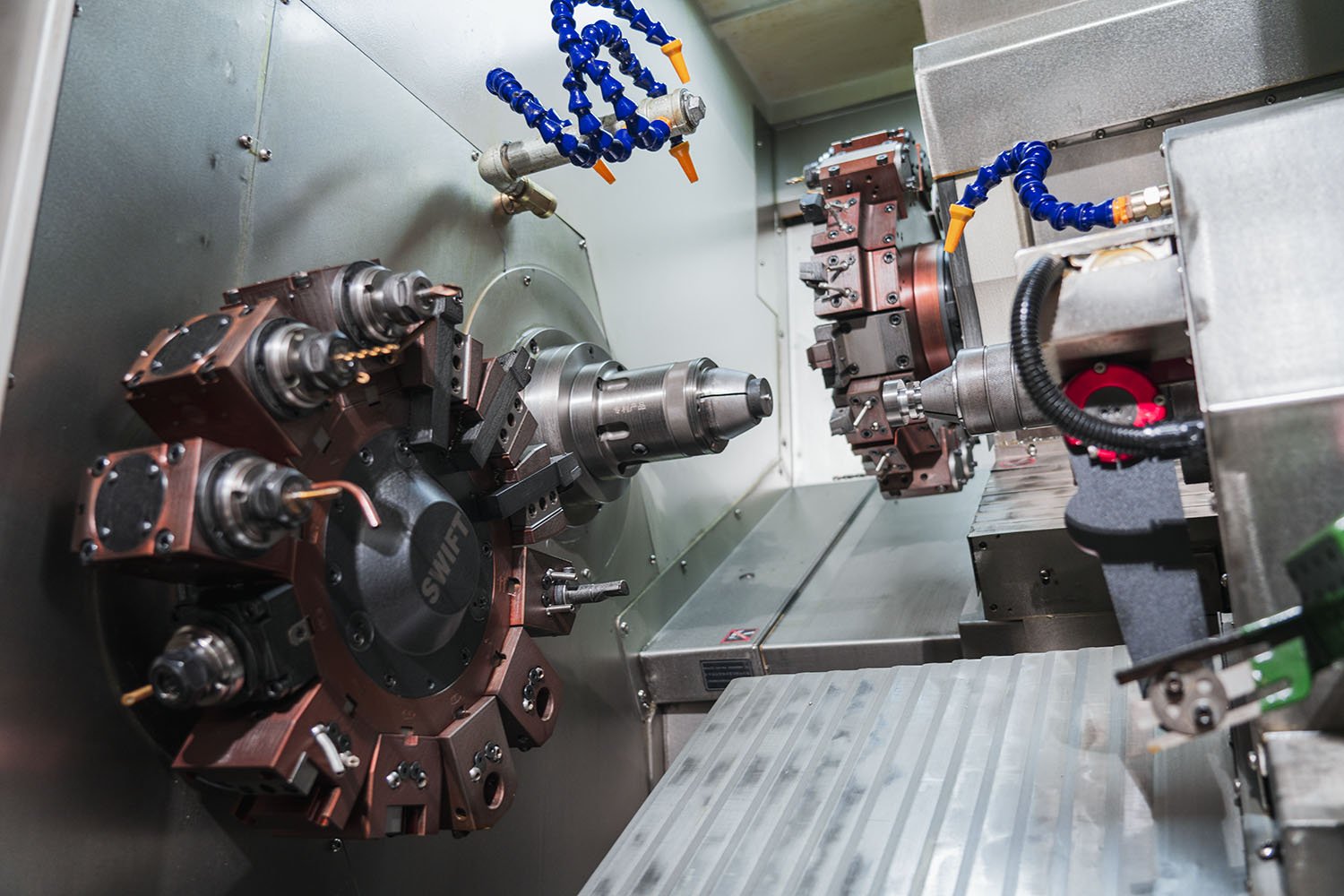

Multiple-turret Lathes

Turrets within the work envelope allow for more adaptable machining. The production of low volume, wide variety parts can be done economically by integrating more tools and alternatives.Our dual spindle lathes are also popular with customers who appreciate the advantages of a durable, technologically sophisticated dual spindle multi-turret lathe that shortens cycle and changeover times.Having more spindles operating inside the machine can result in a clear competitive advantage, regardless of the type of equipment or language utilized.