The difference between servo turret and power turret of CNC lathe?

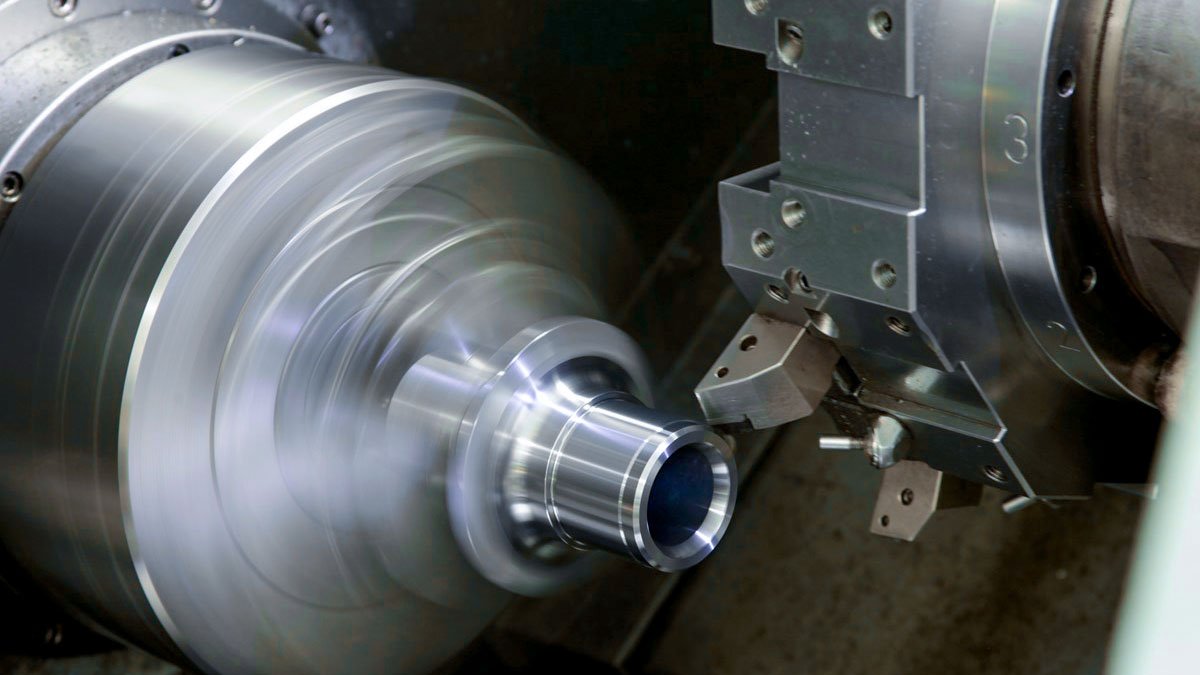

Turret CNC lathe is a very important part of CNC lathe, at present, domestic CNC turret is mainly electric, divided into vertical and horizontal, with four stations, eight stations, ten stations and twelve stations, etc., which can rotate in forward and reverse directions and select knives nearby, and is used in various CNC lathes.

What is a Power Turret?

It is a power turret for turning and milling machining, belongs to the turret for CNC turning and milling machine tools, includes a box, there is a motor installed in the box, the motor includes a motor stator and a motor rotor, the motor stator is fixedly mounted on the box, there is a hollow spline shaft fixedly connected in the middle of the motor rotor, one end of the hollow spline shaft is connected with a clutch, the clutch includes a clutch movable tooth and a clutch fixed tooth, the clutch The movable teeth are connected to the hollow spline shaft, the movable teeth of the clutch can move along the axial direction of the hollow spline shaft, the fixed teeth of the clutch are connected to a first drive shaft which passes through the hollow spline shaft, and the other end of the first drive shaft is connected to a first spiral bevel gear.

What is a Servo Turret?

The CNC lathe machine tool turret or turret head are other names for the tool turret. The tooling is installed on one of the parts of a CNC turning center. The complete tool turret disc of a turret head is where the tools are all mounted. A tool turret with motion capabilities is known as a servo turret. Turrets are turned or moved by the AC, sometimes DC, servo motor, or a compatible AC servo driver.

Typically, a hydraulic or pneumatic power system is used to clamp and unclamp the servo turret heads. A tool turret typically only has one axis of motion, however certain CNC turning centers have multi-axis turret heads that can be moved by the CNC machine's motors.

Advantages of the Servo Turret

The turret's flexibility is its primary benefit. A servo turret can hold more tool stations because of its higher power output. There are four to eight tool stations on a turret head in a typical machining operation, but up to twelve or even more tool stations can be found on a servo turret during a larger-scale CNC machining operation.

There are pieces of tool holders on the turret disc at the tool stations of the turret head. The turret head can handle items with a wider diameter. More cutting tools can be fitted onto a turret head since some tool stations on a turret disc support multiple tool holders. The CNC machine can allow more machining operations on more axes with the tooling turret. The turrets have consequently steadily evolved into a requirement on larger CNC turning centers and other kinds of multifunction machines.

How to distinguish the difference between servo turret and power turret?

In general, the servo turret can only install turning tools, there is no power function so it is only suitable for turning, and this is the key difference. The power turret can install both turning and milling tools, so it can both turn and mill, it is a real sense of turning and milling compound.

Our SL-46 is a good choice if you need a cost-effective CNC lathe with turning and milling functions.

Welcome to chat with us privately, I will be glad to hear from you!