CNC Milling and Turning

When customers need a metal product with a complex shape, they frequently ask for CNC machine. While it is popular to use this broad word to refer to any manufacturing method, CNC machining actually encompasses two distinct processes.

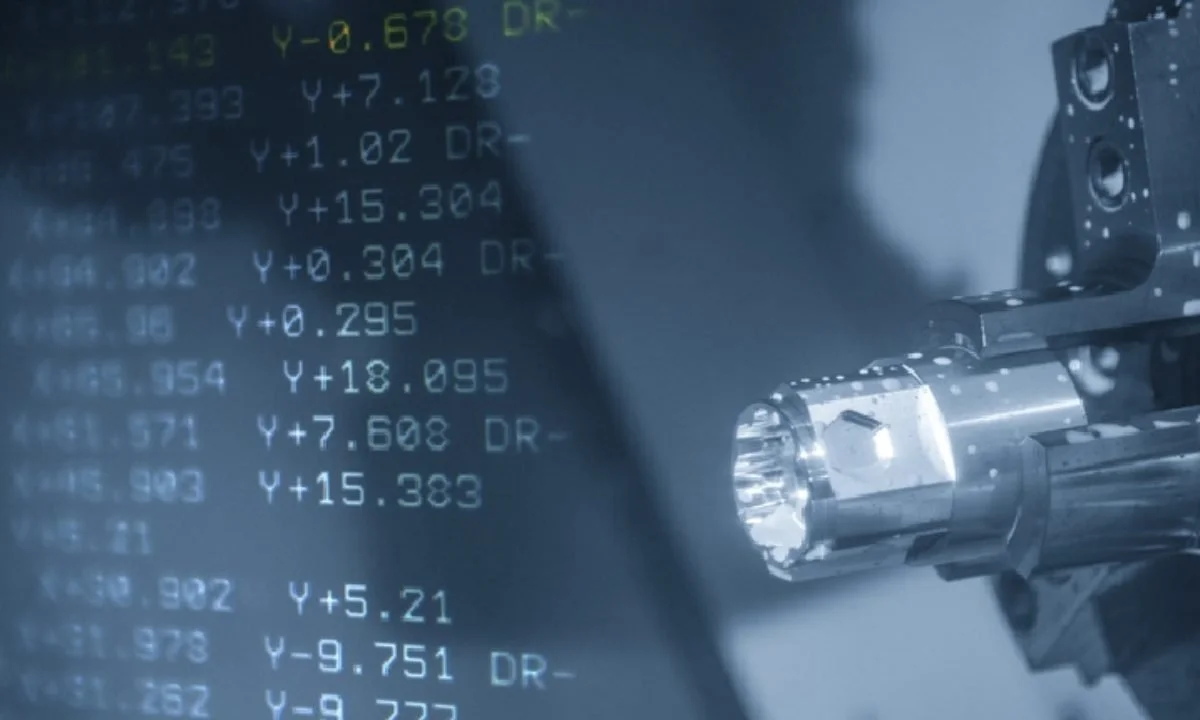

In recent years, computer numerical control (CNC) technology has dominated the metal forming business, as it provides enhanced precision and reproducibility that manual operations cannot match. It might be tough to discern between CNC technologies and what they are used for with so many on the market. While CNC milling and turning have many similarities, they also have some significant distinctions.

What is the Term of CNC Milling?

CNC milling is a mechanical process that produces custom-designed parts or components by.CNC milling is a mechanical process that uses rotating multipoint cutting tools and computerized controls to remove material from a workpiece in order to generate custom-designed parts or components. Three linear degrees of freedom are common in these systems. While the workpiece remains immobile, they can freely move about the X, Y, and Z axes. Milling is more ideal for prototyping and short production runs because of this constrained dimensional operation, which limits the speed of operations.

What Is the Term of CNC Turning?

CNC turning is a manufacturing method that involves rotating material bars in a chuck while feeding a tool to remove material until the required form is attained. Subtraction machining is so named because the required shape is achieved by removing material.

Understanding the Differences Between CNC Milling and Turning

While CNC milling and CNC machining are essentially synonymous, CNC turning is often faster and easier to use than milling. CNC milling is limited by the cutting tool's range of motion. CNC turning is less efficient in terms of material conservation, but it provides for more complicated design alternatives and speedier processes.

Although all of the work can be done from one side of the CNC turning center, some models have the main spindle and a sub-spindle for even faster operation. The workpiece is partially machined by the main spindle, which is then shifted to the sub-spindle to finish the task on the other side of the part. CNC turning operations are suited for big production runs with short lead times due to their speed.

How To Choose CNC Milling and Turning Machines?

CNC milling's production capabilities encompass a variety of procedures, including:

Chemical, Thermal, Electrical, Mechanical etc.

CNC mills have a higher material conservation efficiency, which lowers material costs over time. CNC mills create sophisticated short-run production parts, precision components and parts, and prototype parts.

For CNC turning lathes, they are used to perform operations like:

Boring, Drilling, Facing, Grooving, Knurling, Parting.

Particularly, for some industries like:

Woodworking, Electrical industry, Electrical discharge machining (EDM), Metal removing (in automotive or manufacturing), Material fabrication

It would be perfect to integrate the CNC milling with the CNC turning center when you get some multi-task jobs. Therefore, we developed the revolutionary turn-mill Complex CNC center to fulfill the demand for CNC milling and turning in one unit.

SL 46 CNC Mill/Turn Machines are multi-function CNC machines used for producing complex workpieces in one operation. These machines are capable of turning a workpiece and applying rotating tooling operations such as cross-drilling, tapping, slotting, and milling. A part requiring a variety of operations can be machined in one setup. All these processes combined in one complete cycle allow for faster part making, higher accuracy (no re-chucking), and fewer set-up times. Smartlathe CNC mill/turn complex CNC centers offer those advantages at very affordable prices.