Smart VMC

VMC H800

The VMC H series, with milling, drilling, tapping, and EDM capabilities, is widely used in mold making, automotive, aerospace, electronics, medical devices, and engineering. Known for precision and versatility, it handles complex shapes and hard materials, meeting diverse modern manufacturing needs.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

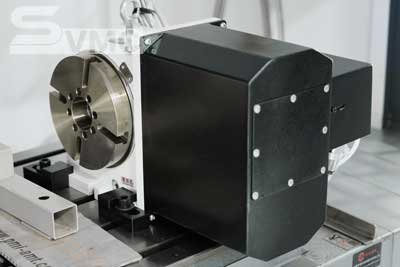

4th-Axis

Tool Setter

Customized Fixture

Mitsubishi controller

Chain Chip Conveyor |

||||||