Calculation of drilling parameters

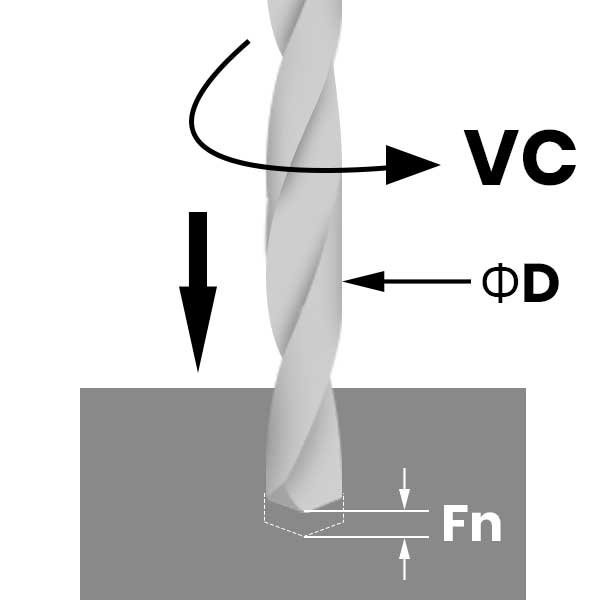

Calculate the cutting speed based on the drill diameter and spindle speed.

D — Drill diameter

n — Spindle speed

C — Circumference

Vc — Cutting speed

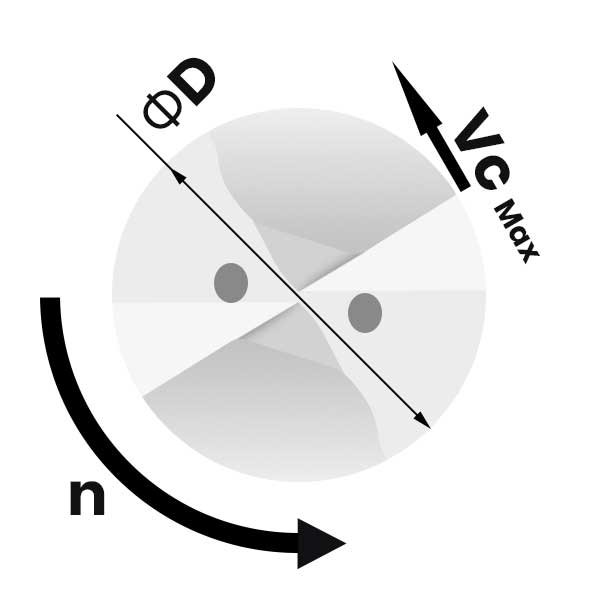

Cutting speed is the relative linear speed between the cutting edge and the workpiece. At every point, the cutting speed is the product of the drill's rotational speed (spindle speed) and the circumference. At the center of the drill, the cutting speed is always zero, and it gradually increases as you move away from the center. Therefore, in drilling, the term "cutting speed" refers to the maximum cutting speed occurring at the drill's outer diameter. On the surface of the drill, the cutting speed varies according to the distance from the center.

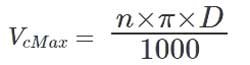

Maximum drilling speed

D-Drill bit diameter (millimeters)

n-rpm

Vc max-Max. Cutting speed (meters per minute)

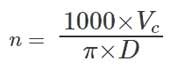

Spindle Speed:

Drilling manuals or experience tell us which cutting speed to use for a given operation. On the other hand, CNC machines are programmed using spindle speed. Therefore, we typically need to calculate the RPM based on the given cutting speed in order to program the machine or to ensure that the desired speed is within the machine's limits. It is calculated by dividing the cutting speed by the circumference of the drill bit.

D-Drill bit diameter (millimeters)

n-rpm

Vc-Cutting speed (meters per minute)

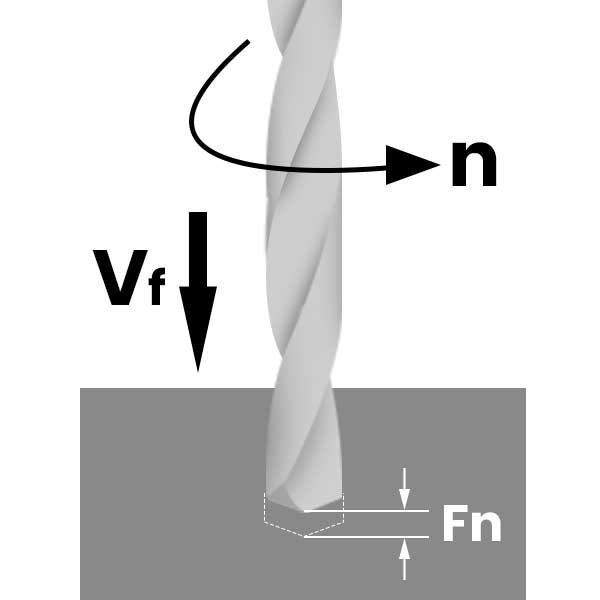

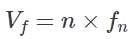

Drilling Speed:

The drilling speed of the drill bit is determined by the spindle speed and the feed per revolution.

n — Spindle speed

Fn — Feed per revolution

Vf — Penetration rate

Drilling speed is the linear speed at which the drill bit penetrates the material. To calculate it, we first need to obtain the feed per revolution (Fn), which is the distance the drill bit travels for each revolution of the spindle. This parameter is usually available from the drill bit supplier's catalog. The drilling speed is the product of the spindle speed and the feed per revolution.

Material Removal Rate:

D-Drill bit diameter

Fn-Feed rate / Rotation

Vc-Cutting speed

Material Removal Rate (MRR) is measured in cubic inches (or cubic centimeters) per minute, representing the amount of material drilled per minute under a set of cutting conditions. It is the product of cutting speed, feed per revolution, and drill bit diameter.

D-Drill bit diameter (millimeters)

Fn-Feed per revolution [mm/rev]

Vc-Cutting speed (meters per minute)

Q-Metal removal rate [cm³/min]

Drilling time refers to the time required to complete one hole under specific cutting conditions.