What is a push-type chuck?

A push-type chuck is a workpiece holding device commonly used in turning operations. Known for its efficient and precise clamping, it is widely employed in various CNC machine tools, especially in scenarios requiring high repeat positioning accuracy and stable clamping force.

Working Principle

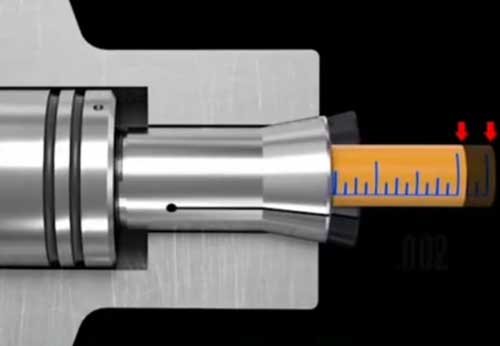

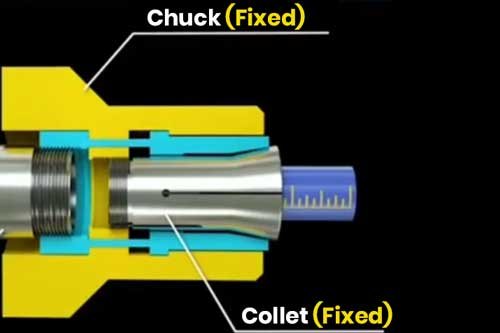

The push-type chuck transmits clamping force evenly to the surface of the workpiece through an internal thrust mechanism, ensuring a secure hold. The clamping action is usually driven hydraulically, pneumatically, or electrically, with axial thrust applied to an internal wedge structure to achieve radial clamping.

Types of Push-Type Chucks:

Standard Push-Type Chuck Seats: 163E, 173E, 185E, 193E. Using the front push chuck.

Universal Push-Type Chuck Seats: A2-4, A2-5, A2-6, A2-8. Using a back pull chuck.

Advantages

1. High-Precision Positioning

Push-type chucks provide exceptional repeat positioning accuracy, making them suitable for scenarios with stringent machining precision requirements. They are particularly useful when paired with feeders and dual-spindle machines requiring precise workpiece alignment.

2,Strong Clamping Force

With a well-designed mechanical structure, push-type chucks deliver stable and powerful clamping force, ensuring the workpiece remains secure without shifting or loosening during machining.

3,Wide Applicability

Compatible with a variety of workpiece sizes and shapes, they are suitable for machining shafts, discs, and other components.

4,Ease of Operation

The automated operation design of the chuck significantly improves setup efficiency, meeting the demands of modern production lines.

Applications

Push-type chucks are extensively used in precision machining scenarios in industries such as automotive parts, aerospace, medical devices, and electronics. They are especially suitable for processing high-hardness materials and complex-shaped components.

Differences Between Push-Type and Pull-Type Chucks

|

|

|

|

|

Clamping Direction |

The push rod is not connected to the chuck seat; pushing the workpiece does not cause it to move. |

The pull rod pulls back, causing the chuck to retract the workpiece. |

|

Positioning Feature |

Requires a front positioning block to support the workpiece. |

The spindle end directly positions the workpiece. |

|

Suitable Workpieces |

Long shafts, ring-shaped workpieces. |

Short workpieces, high-rigidity machining pieces. |

|

Rigidity and Precision |

Moderate rigidity, suitable for precise light cuts. |

Higher rigidity, suitable for heavy and high-speed machining. |

|

Application Scenarios |

Primarily used in dual-spindle CNC lathes to prevent workpiece deformation during docking and ensure consistent workpiece length . |

Mainly used in single-spindle CNC lathes. |