What is countersinking

Introduction to countersinking

Countersinking is a metal processing method that refers to processing cylindrical countersunk holes, conical countersunk holes, and boss end faces on processed holes.

The tool used for countersinking is called a countersink drill, which is generally made of high-speed steel. Countersink drills for processing large-diameter boss sections can be made with carbide reground blades or indexable blades, fixed to the tool body by inserts or machine clamps.

Types of countersinking

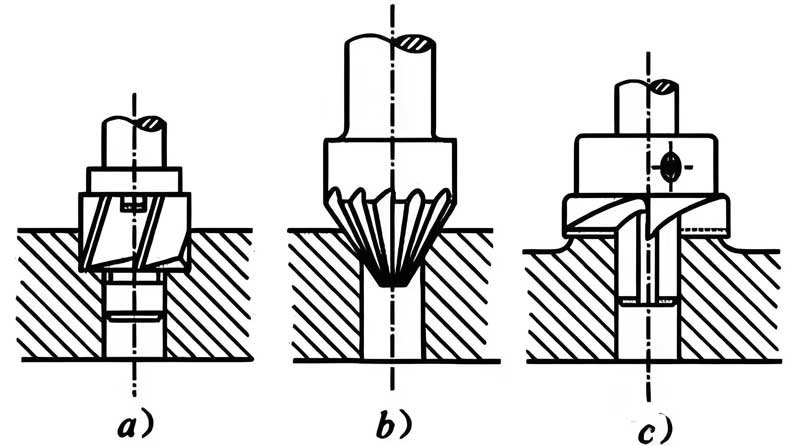

Countersinks are divided into three types: cylindrical countersinks, conical countersinks, and end countersinks.

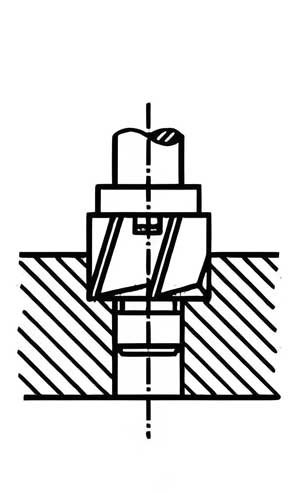

Cylindrical countersink

The cylindrical countersink is used to countersink cylindrical holes. The main cutting function of the cylindrical countersink is the end face blade, and the bevel angle of the spiral groove is its rake angle. There is a guide column at the front end of the countersink, and the diameter of the guide column is closely matched with the existing hole of the workpiece to ensure good centering and guidance.

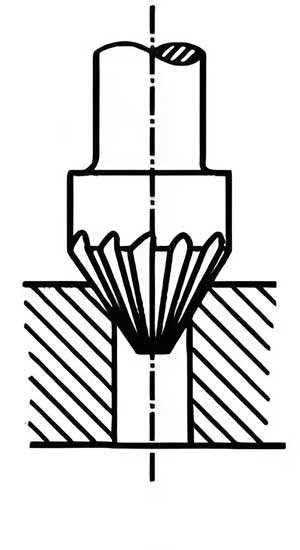

Conical countersinks

Conical countersinks are used to countersink conical holes. The cone angle of the conical countersink varies according to the requirements of the workpiece's conical countersink hole. There are four types: 60°, 75°, 90°, and 120°. Among them, 90° is the most commonly used.

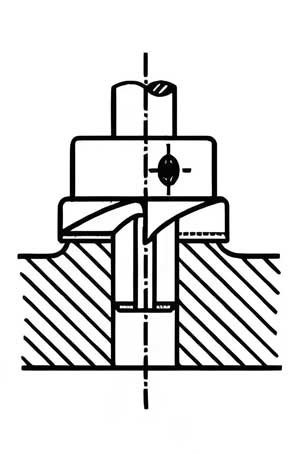

End countersinks

The end face countersink is specially used to countersink the end face of the hole. The end face countersink can ensure the verticality between the end face of the hole and the center line of the hole. When the processed hole diameter is small, in order to keep the tool bar at a certain strength, a section of the diameter of the tool bar head can be matched with the processed hole to ensure a good guiding effect.

Precautions for countersinking

The countersinking method is basically the same as the drilling method. The main problem when countersinking is that the end face or cone surface of the countersinked hole will produce vibration marks due to the vibration of the tool. The vibration marks are particularly serious when using a twist drill to convert a countersink. In order to avoid this phenomenon, the following points should be noted when countersinking.

The cutting speed during countersinking should be lower than that during drilling, generally 1/2 to 1/3 of the drilling cutting speed.

The countersink drill arbor and blade must fit properly, be clamped firmly, guide reliably, press the workpiece tightly, and no vibration should occur during countersinking.

When countersinking steel parts, due to the high cutting heat, lubricating oil should be added to the guide column and cutting surface.