Modularized Design

Ensure Highly Consistency and Engineering Precision.

Standardized Production

Competitive Price & Ready-to-Ship Models are Available.

Customized Solution

Technical Support with Machining Analysis & Optimism.

Customer Cases

OUR PRODUCTS

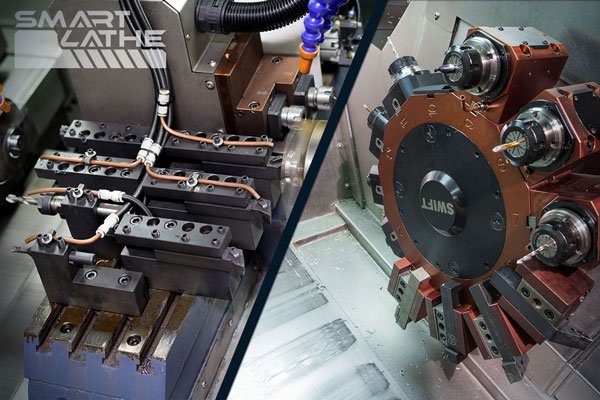

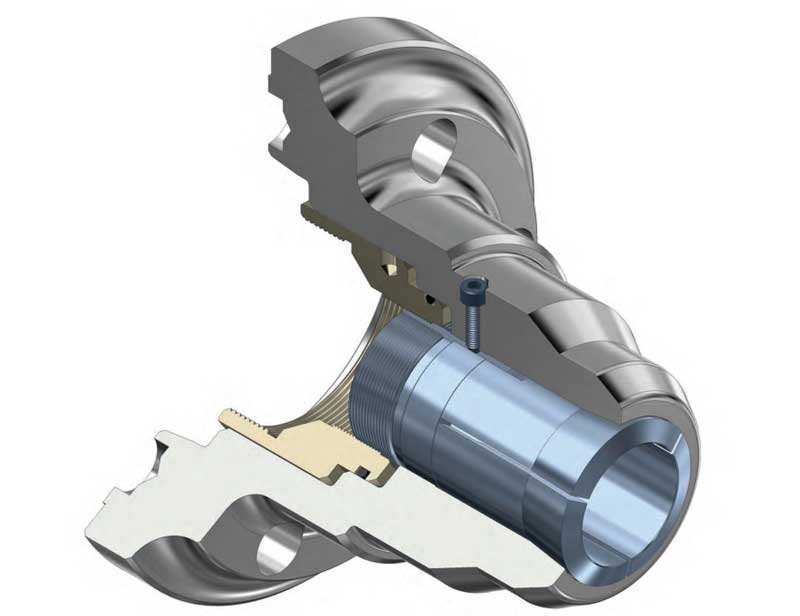

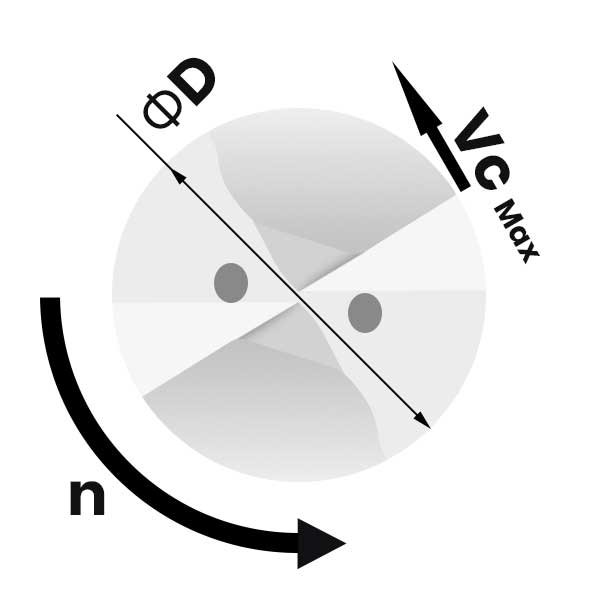

Living Tools

Y-Axis Milling

Slant Bed

Gang Type

Servo Spindle

Collet

High Rigidity

Y-Axis Turret Type

Tailstock

Automatic

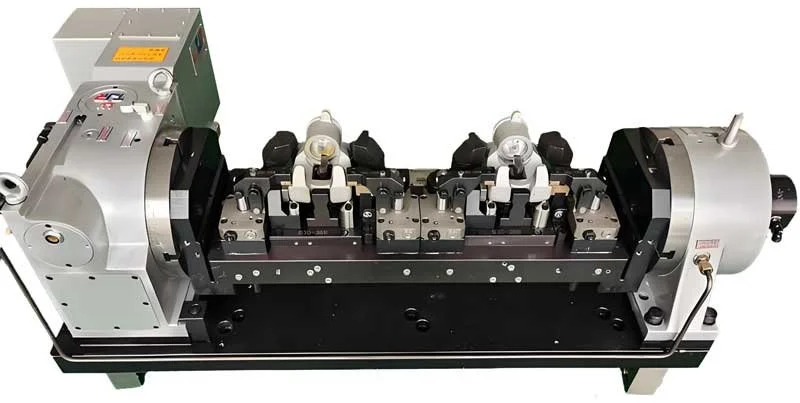

Dual Spindle

Gang Type

Turret Type

Dual Channel System

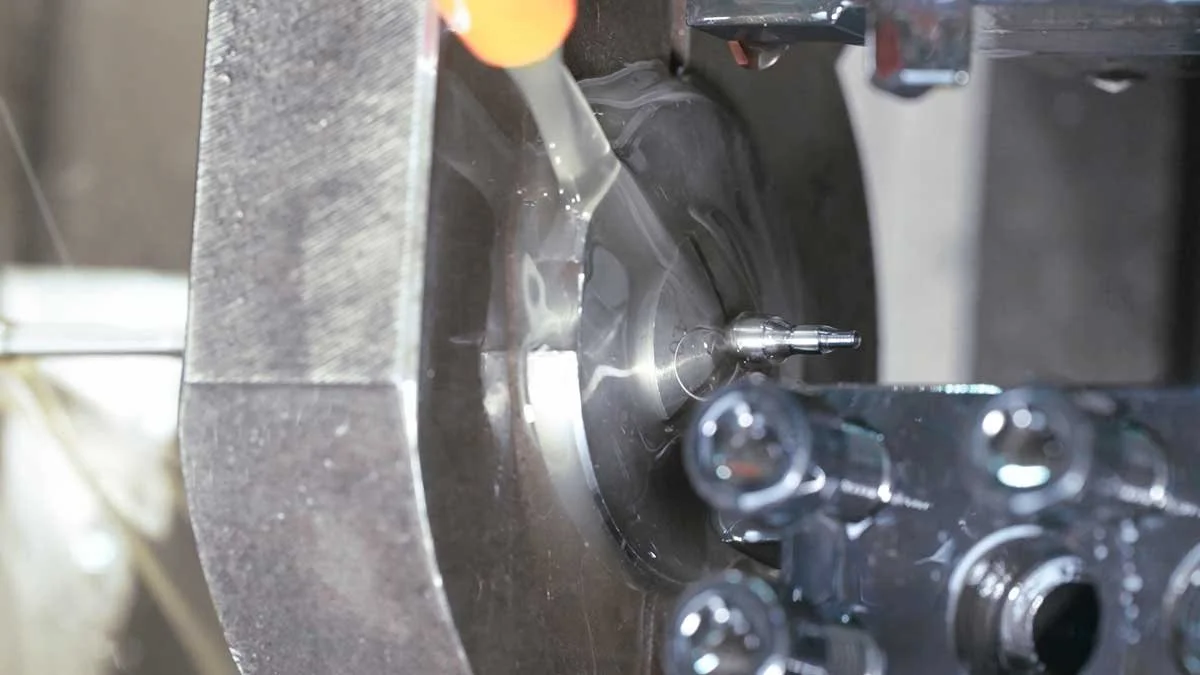

Turning & Milling

Swiss Type

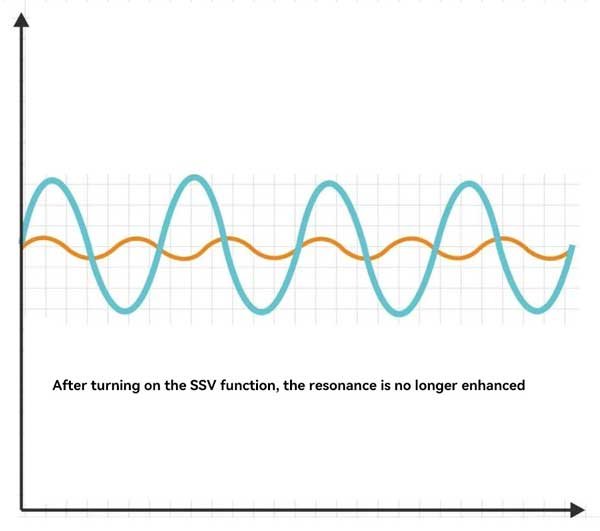

Smartbrain System

Carousel

BT30/40

High Rigidity

Synchronous-action

BT30/40 High-speed

Heavy Duty

Side-mounted

BT40

AUTOMATIC SOLUTIONS

At Smartlathe CNC, we pride ourselves on being a leading supplier of reliable, stable, and cost-effective CNC lathes. Beyond providing high-quality machines, we also offer comprehensive automation solutions to enhance your production efficiency. Our primary automation options include truss manipulators and robotic arms. These automated CNC lathe solutions significantly boost productivity while reducing manual labor intensity.

Configurations on Demand

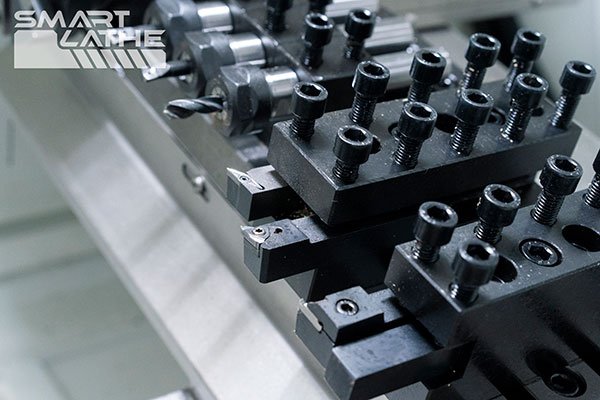

Thanks to the modularized designs, Smartlathe is capable of providing the various multi-functional tools & fittings to perfectly match the tailored machining requirements.

Y-axis Living Tools

3 Jaws Chuck

Servo Turret

Step Type Live Tools

Oil Bar Feeder

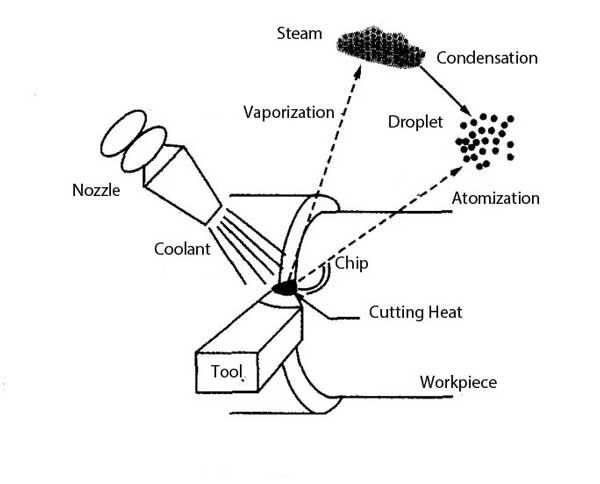

Oil Mist Collector

Servo Bar Feeder

4+4 Living Tools

Tools Setter

Power Turret

Part Catcher

Tailstock

We Extend the Limit of CNC Turning Process!

Chip Conveyor

4th Axis

Auto Tools Setter

Customized Fixture

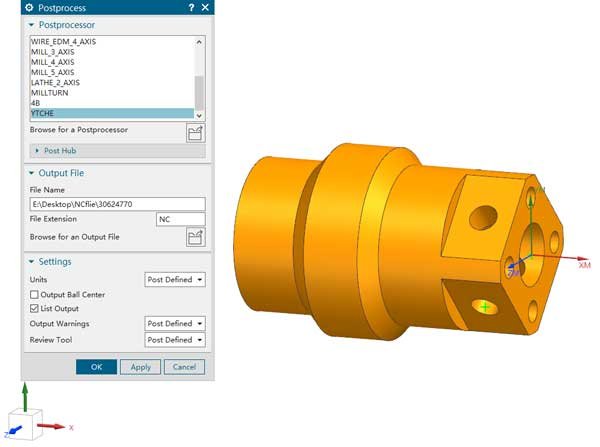

Send us a drawing to evaluate.

STEP / STP / SLDPRT / PRT / DWG / DXF files.

All files are secure and confidential.